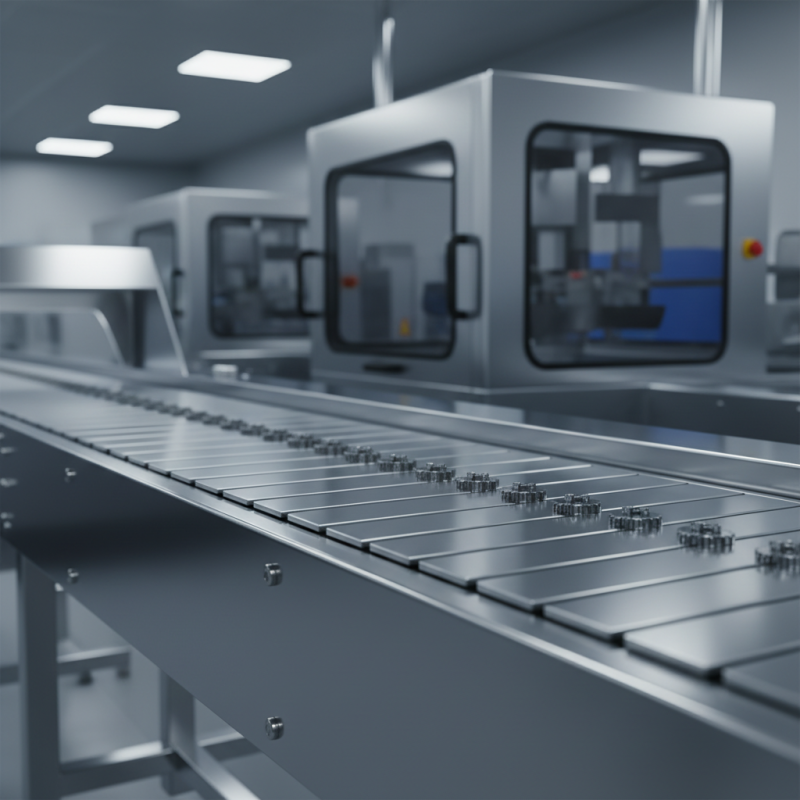

In today’s industrial landscape, efficiency and durability are paramount. A Stainless Steel Conveyor Belt emerges as a popular choice for many companies. These belts offer numerous advantages that can significantly impact production processes.

One clear benefit is their resistance to corrosion. This quality ensures that the conveyor belts maintain their integrity in harsh environments. Additionally, the smooth surface of a Stainless Steel Conveyor Belt allows for easy cleaning. This feature is essential in industries prone to contamination. The longevity of these belts also reduces the frequency of replacements, saving both time and money.

However, not all companies fully understand their potential drawbacks. For instance, while they are strong, they can be more expensive than alternatives. Organizations must weigh the initial investment against long-term benefits carefully. It’s crucial to consider both the advantages and challenges of using a Stainless Steel Conveyor Belt in various settings. Balancing these factors can lead to better decision-making in the industry.

Stainless steel conveyor belts offer numerous advantages, particularly in food processing industries. These belts are non-corrosive and resistant to high temperatures. This durability is crucial in environments where hygiene and safety are paramount. According to a report by the Food Safety Authority, nearly 60% of food contamination cases are linked to equipment materials. Using stainless steel helps mitigate this risk.

The ease of cleaning stainless steel is a significant benefit. Its smooth surface prevents the buildup of bacteria. In fact, studies show that stainless steel can be cleaned in less than half the time compared to plastic counterparts. Hygiene is not just a standard; it’s essential in food processing.

**Tip:** Regular maintenance of conveyor belts can extend their lifespan. Consider a weekly inspection schedule. Look for wear and any signs of corrosion.

Additionally, stainless steel is known for its strength. It withstands heavy loads and frequent use. Many factories report a reduction in downtime by 20% due to reduced maintenance requirements. However, while these belts are robust, they can be more expensive upfront. It's important to weigh the long-term savings against initial costs.

**Tip:** When selecting a conveyor belt, ensure it fits your specific processing needs. Analyze your production volume and product type to make an informed decision.

Stainless steel conveyor belts are increasingly popular in various industries. They are especially valued for their corrosion resistance. This feature ensures that the belts last longer, even in harsh environments. Unlike other materials, stainless steel does not easily degrade. It can withstand exposure to moisture, chemicals, and temperature changes. This durability leads to fewer replacements and less downtime.

Another benefit is the reduction in maintenance costs. With a longer lifespan, companies save money over time. Regular cleaning is simpler because stainless steel doesn’t harbor bacteria or grime as easily. However, some may overlook the initial investment required for stainless steel. It can be more expensive compared to other materials. This upfront cost might deter small businesses.

While the long-term savings are apparent, it is essential to assess the operational environment. Not every company may find stainless steel the best fit. Some might experience excessive wear in specific conditions. This raises questions about the suitability of stainless steel for all applications. Each industry has unique needs, so careful evaluation is necessary before making a choice. Balancing cost, durability, and specific use cases is key.

Stainless steel conveyor belts are a popular choice in various industries, especially food processing. Their hygienic design plays a crucial role in meeting FDA guidelines. These belts can withstand harsh cleaning solutions and high temperatures. This durability helps maintain a clean environment, essential for food safety.

One key benefit is their smooth surface. This feature minimizes harborage points for bacteria. However, even with proper design, regular maintenance is necessary. Dust and dirt can accumulate in areas otherwise accessible, which may compromise hygiene efforts. Workers need to conduct routine inspections.

Another aspect to consider is the metal's resistance to corrosion. It allows for longevity in equipment, but neglecting small scratches can lead to rust. Regularly checking for surface damage is vital. While stainless steel provides many advantages, its effectiveness relies on proactive upkeep to truly meet safety standards.

| Benefit | Description | Impact on Food Safety |

|---|---|---|

| Hygienic Design | Smooth surfaces that prevent bacteria buildup. | Reduces contamination risks. |

| Corrosion Resistance | Resistant to rust and oxidation. | Maintains product integrity over time. |

| Durability | Long-lasting materials reduce replacement needs. | Ensures consistent safety standards. |

| Easy Cleaning | Simple to sanitize and maintain. | Supports compliance with hygiene regulations. |

| Temperature Resistance | Withstands high and low temperature extremes. | Protects food quality under various conditions. |

| Non-Reactive | Does not react with food products. | Ensures the safety and taste of food. |

| Versatility | Can be used in various industrial applications. | Flexibility in food handling processes. |

| Customizability | Options for tailored designs to meet specific needs. | Enhances operational efficiency. |

| Regulatory Compliance | Meets FDA and other industry standards. | Ensures product safety and accountability. |

| Cost-Effectiveness | Reduces maintenance and replacement costs over time. | Optimizes budget allocation for safety protocols. |

Stainless steel conveyor belts are vital for industries operating in extreme conditions. Their high temperature tolerance ensures operational efficiency, even at elevated levels. These belts can typically withstand temperatures up to 1,200°F (650°C). Such resilience allows for smooth functioning in heat-intensive environments, like food processing or metal forging.

When comparing materials, stainless steel shows superior performance. A 2020 industry report highlights that steel belts reduce downtime by 30%. This efficiency is crucial for maintaining production schedules. Without reliable conveyor systems, production can falter. Many businesses reported losses due to equipment failure.

**Tip:** Regular maintenance is key. Inspect belts frequently for signs of wear. This practice can prevent unexpected breakdowns.

Even with their advantages, stainless steel belts come with considerations. They can be heavier than other materials, affecting energy consumption. An analysis from 2021 suggests that energy costs can rise by 10% with heavier systems. Balancing efficiency and weight is essential for any operation.

**Tip:** Evaluate your energy consumption. Adjust belt designs to reduce costs without sacrificing heat tolerance.

Understanding these dynamics is crucial for optimizing operations. High-performance solutions exist, yet businesses must adapt their strategies as conditions change.

Stainless steel conveyor belts offer exceptional versatility in material handling. They are suited for various industries, including food processing, pharmaceuticals, and manufacturing. The non-corrosive nature of stainless steel ensures hygiene in food applications. It resists bacteria and contaminants, promoting a safer working environment.

In the mining and automotive industries, these belts can handle heavy loads. Their strength supports a wide range of materials. However, not all stainless steel belts are suitable for every task. Understand the specific requirements before selecting a belt.

Tip: Consider the environment when choosing a conveyor belt. Extreme temperatures and humidity can affect performance. Additionally, proper maintenance is crucial. Regular inspections prevent unexpected breakdowns and prolong lifespan. Always assess the cost versus durability. Sometimes, cheaper options lead to higher long-term expenses.