Heating systems play a crucial role in various industries. One critical component in these systems is the Furnace Mesh Belt. It enhances the efficiency of heating processes and can impact overall performance. Choosing the right Furnace Mesh Belt can be complex. The market offers numerous options, each with unique features.

Consider the material used in these belts. Stainless steel is popular for its durability and heat resistance. However, aluminum belts might be lighter but could lack longevity. Efficiency is not just about material; it's about design too. Some belts are designed for uniform heat distribution, while others focus on speed. This differentiation is vital for specific applications.

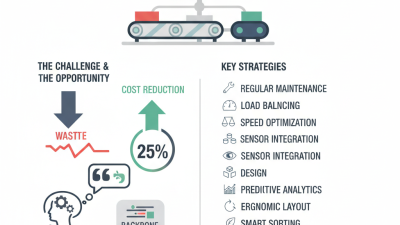

Users often overlook maintenance when selecting Furnace Mesh Belts. Regular checks can prevent breakdowns. A well-maintained belt functions better, leading to cost savings. When researching options, clarity on your industry needs is crucial. Look for options that align with your heating goals. Balancing performance and practicality is challenging, but necessary for optimal results.

When selecting furnace mesh belts, understanding the various types can greatly enhance performance. For example,

stainless steel belts are a popular choice. They provide excellent heat resistance and durability. They perform admirably in temperatures reaching

1000°F (540°C). However, corrosion can be a concern in high-moisture environments. This leads manufacturers to often seek alternative materials,

which can be a learning opportunity.

Another option is woven wire mesh belts. They allow for even heat distribution, improving overall efficiency. Reports suggest that effective heat transfer can increase energy savings

by up to 30%. These belts, however, may require more frequent maintenance. Ensuring proper tension and alignment can mitigate operational issues.

User feedback often reflects the need for ongoing evaluation when using these materials.

Finally, composite belts made of fiberglass and other materials are gaining popularity. They offer a lightweight alternative while still withstanding high temperatures.

Data indicates they can reduce energy consumption by roughly 15% compared to traditional options. Nonetheless, their long-term durability under extreme conditions remains an open question.

Balancing initial costs and future savings is essential in this decision-making process.

When exploring efficient furnace mesh belt options, key materials play a vital role. These materials affect both performance and durability. Common choices include stainless steel, carbon steel, and special alloys. Each material has unique properties that cater to specific heating applications. For instance, stainless steel offers excellent corrosion resistance. It also withstands high temperatures well.

Carbon steel is another popular option. It is often more cost-effective. However, it may require coatings to enhance its resistance to oxidation. Using uncoated carbon steel can lead to rust, decreasing the belt's lifespan. Consider the application environment before selecting materials. The right choice can enhance heating efficiency significantly.

**Tip:** Always evaluate the thermal conductivity of the chosen material. Higher conductivity can lead to faster heating.

Another aspect to consider is the design of the mesh belt. Different weave patterns can affect airflow and heat transfer. A tighter mesh might provide better support but could restrict airflow. This is a balance to consider.

**Tip:** Regularly inspect the mesh for wear and tear. Minor issues can escalate, leading to larger failures.

The performance of furnace mesh belts heavily relies on material selection and design. Careful consideration can help avoid inefficiencies and prolong the equipment's lifespan.

Selecting the right furnace mesh belt is crucial for optimizing heating efficiency. One important factor is material. Stainless steel is popular for its durability. However, it can be costly. On the other hand, fiberglass offers a lightweight solution. Yet, it may not withstand high temperatures as effectively. Evaluate your specific heating requirements before making a choice.

Another key consideration is the belt's design. A flat mesh design allows for even heat distribution. This promotes uniform heating and reduces hotspots. Conversely, a multi-layered belt might provide better insulation. This can lead to energy savings. However, it could complicate maintenance. It's essential to find a balance between functionality and ease of upkeep.

Finally, think about the belt's size and compatibility with your furnace. An ill-fitting belt can disrupt airflow. This can lead to inefficiencies and potential damage. Measure your furnace carefully. It’s often easier to go for adjustable options. Make a list of your needs. Reflect on your heating goals frequently. The right choice can make a significant difference.

This chart showcases the evaluation scores of different factors to consider when selecting a furnace mesh belt for efficient heating. The scores range from 1 to 10, with higher scores indicating better performance in areas such as material durability, heat resistance, energy efficiency, cost, and maintenance requirements.

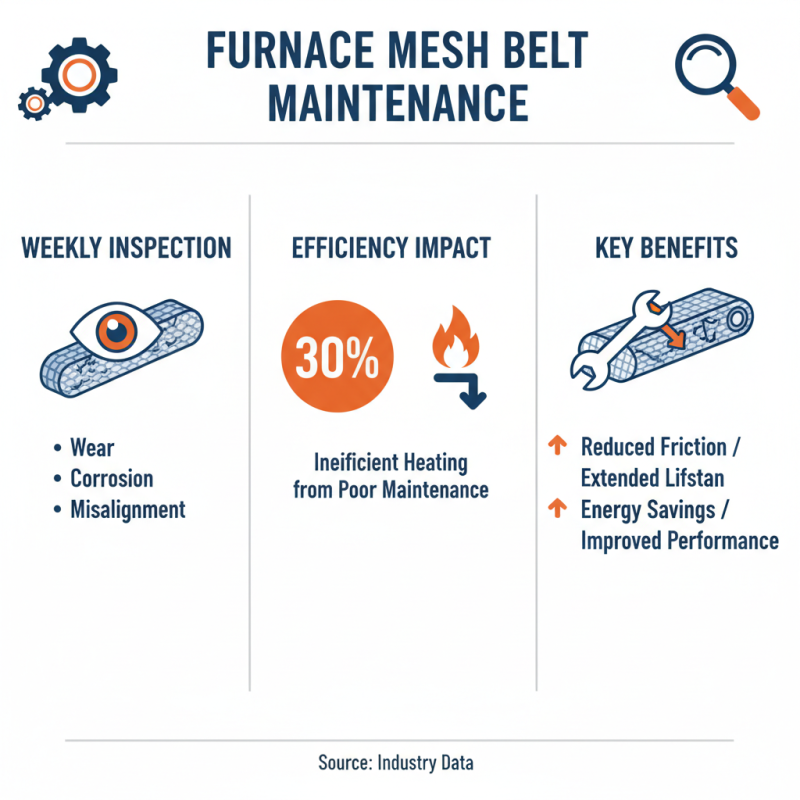

When maintaining furnace mesh belts, regular inspection is crucial. Operators should check for signs of wear, corrosion, or misalignment weekly. According to industry data, about 30% of inefficient heating issues are linked to poorly maintained belts. Keeping the belts properly aligned can help reduce friction and extend their lifespan. A small adjustment can lead to significant energy savings and improved performance.

Cleaning is another important maintenance task. Dust and debris can accumulate, leading to overheating. Routine cleaning can enhance heat distribution and improve efficiency by up to 15%. Over time, many facilities neglect this step. This neglect can result in costly repairs and reduced operational efficiency. Regularly scheduled cleanings can prevent these issues.

Make sure to lubricate the mesh belt regularly. Proper lubrication helps in maintaining flexibility and reduces wear. Interestingly, failure to lubricate can decrease the belt's lifespan by nearly 40%. Operators often overlook this simple task. Skipping lubrication might seem minor, but it has long-term repercussions. Ultimately, each maintenance step contributes to an efficient heating process.

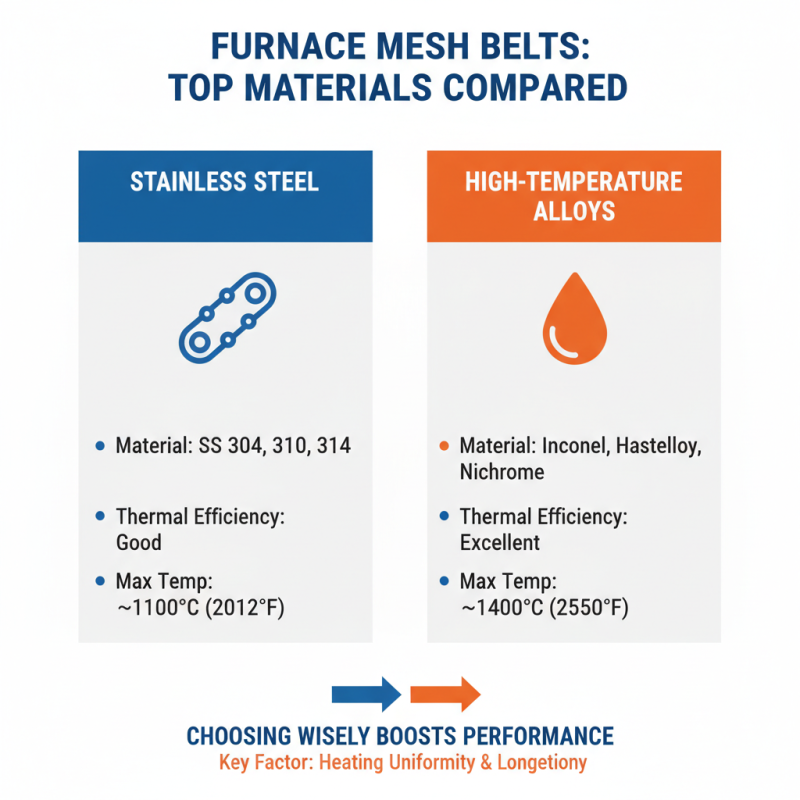

When selecting the best furnace mesh belts, comparing top options is crucial. Various materials affect heating performance. Some belts are made from stainless steel. Others use high-temperature alloys. These choices lead to different thermal efficiencies.

Not all mesh belts perform the same. Some offer better heat distribution; some struggle with hot spots. A few belts may last longer than expected, while others wear out quickly. Durability plays a significant role. Choosing the right one can be tricky, especially for specific applications. The width and thickness of the belt impact its functionality. These factors determine how well the belt holds up under heat.

Investing time in research can pay off. It's not just about choosing a popular product. Actual performance in real-world conditions matters more. The specifications should align with your heating needs. Conducting trials can reveal hidden weaknesses in certain options. The right choice can enhance efficiency and save costs over time. Make sure to consider these elements when deciding.