In the fast-paced world of industrial manufacturing, selecting the right equipment is vital. Wire conveyor belts have emerged as a critical component in various applications. John Stevens, an expert in conveyor systems, emphasizes, “The right wire conveyor belt can significantly enhance process efficiency.” This highlights the importance of making informed choices.

Wire conveyor belts are celebrated for their durability and adaptability. They cater to diverse industrial needs, from food processing to heavy manufacturing. However, not all options are created equal. Factors like material, temperature resistance, and weave type can dramatically affect performance. Many companies overlook these details, leading to inefficiencies.

While the advantages are clear, it’s essential to reflect on your specific needs. A common mistake is to prioritize cost over quality. This often results in higher long-term expenses. Investing in the best wire conveyor belt may require an upfront cost, but it can save money down the line. Careful evaluation is key to achieving optimal results.

Wire conveyor belts are essential in many industrial settings. They are made from metal wires, providing strength and durability. These belts are particularly useful in industries like food processing, automotive, and mining. In fact, according to a recent industry report, the global wire conveyor belt market is projected to reach over $1 billion by 2026, reflecting a steady demand.

One significant reason for this demand is their adaptability. Wire conveyor belts can handle a variety of materials and temperatures. They are suitable for both heavy and light loads. However, selecting the right type can be challenging. Each application has unique requirements, like surface finish and load capacity. In some cases, operators may overlook these specific needs. This can lead to inefficiencies and increased costs.

Another aspect to consider is maintenance. Wire conveyor belts require regular inspection and cleaning. Neglecting this can lead to breakdowns. Some companies may underestimate this need. Yet, proper maintenance can significantly extend the life of a belt. Data suggests that well-maintained belts can perform up to 25% longer than neglected ones. This shows the importance of attentive management in industrial operations.

When selecting wire conveyor belts for industrial applications, several key factors matter. First, the material composition is critical. Stainless steel belts are common for their durability. An industry report shows that stainless steel belts can outlast alternatives by up to 30%. However, they can also be costly, making budget considerations essential.

Another crucial aspect is the belt design. Different designs accommodate various loads and environments. Open mesh styles provide airflow but may be unsuitable for heavy items. Conversely, closed designs support better weight distribution. A study indicates that improper design can lead to a 20% decrease in efficiency. This poses a risk as facilities seek to enhance productivity.

Finally, maintenance plays a significant role. Regular inspections can extend the lifespan of the belts. However, not all teams prioritize this. A survey found that 40% of users fail to schedule regular maintenance. This leads to unexpected downtimes, affecting overall operations. Careful attention to these factors can lead to better outcomes, though many overlook them.

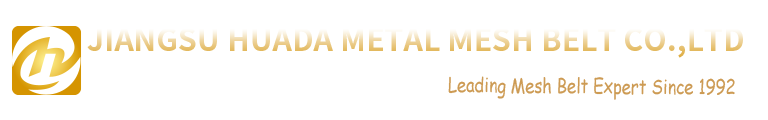

When selecting wire conveyor belts for industrial applications, understanding the options available is key. In 2026, a variety of choices meet diverse operational needs. Some prevalent types include welded mesh, spiral, and flat wire belts. Each design caters to specific tasks, such as food processing, metalworking, or packaging.

Recent industry reports indicate that welded mesh belts experience a 15% growth in demand. They are praised for durability and ease of cleaning. Spiral belts, on the other hand, offer flexibility in tight spaces. Their design allows for smooth transport of small parts. However, proper maintenance is often overlooked, leading to potential downtime. Efficiency can be compromised if issues arise.

Flat wire belts are versatile, but their installation can be tricky. Mishandling during setup may cause tension inconsistencies, affecting performance. According to a survey, 30% of companies struggle with these issues. It's essential to evaluate the needs of your facility carefully. Investing in the wrong type can lead to increased costs and operational inefficiencies. The variety in wire conveyor belts reflects the complex nature of industrial operations.

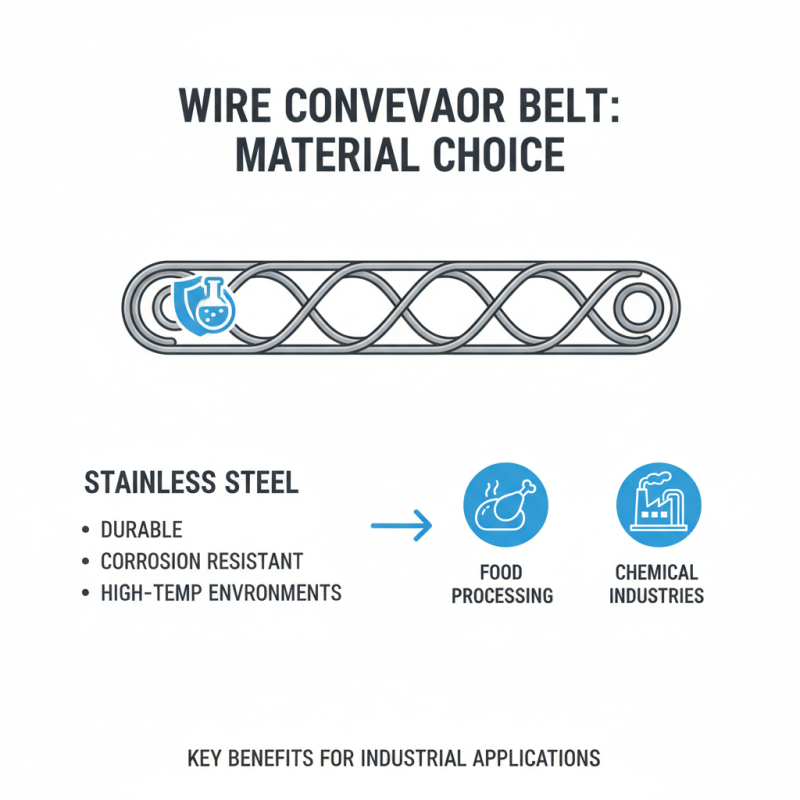

When selecting the right wire conveyor belt, material choice is crucial. Different wire materials offer unique advantages for various industrial applications. Stainless steel is durable and resistant to corrosion. It functions well in high-temperature environments. This makes it suitable for food processing and chemical industries.

In contrast, aluminum wire is lightweight and offers excellent conductivity. It can be used in applications that require frequent movement and quick adjustments. However, aluminum may not be as durable as stainless steel. Users often have to consider the trade-off between weight and strength.

There is also copper wire, known for its thermal properties. It is excellent for heat transfer applications. However, it can be prone to oxidation. This can be a downside in certain environments. Reflecting on these aspects helps in making informed choices. Each material has strengths and weaknesses that must be evaluated.

Wire conveyor belts are crucial for various industrial applications. To ensure their optimal performance, regular maintenance is essential. One key aspect is to regularly clean the belts. Accumulated debris can affect their efficiency and lead to wear. Use appropriate cleaning agents to avoid damaging the material. Ensure that the cleaning process is thorough but gentle.

Another important maintenance tip is to inspect the belts frequently. Look for signs of wear and tear. Check for broken wires or misalignment. Minor issues can escalate if ignored. Keeping an eye on these details can save time and costs. Additionally, lubrication can help maintain smooth operation. Use appropriate lubricants sparingly, as over-lubrication could attract dust and dirt.

Lastly, proper tensioning of the belts matters. A belt that is too loose can slip, while one that is too tight can wear prematurely. Adjustments should follow the manufacturer's guidelines. However, even seasoned professionals can misjudge tension settings. This calls for constant evaluation and adjustments to ensure the best performance.