Choosing the right Woven Wire Mesh can make or break your project. Expert engineer Sarah Thompson emphasizes, "The right mesh determines not just strength, but overall success." This highlights how critical it is to select materials that meet your specific needs.

In many projects, Woven Wire Mesh serves a variety of functions, from filtration to security. Its versatility is undeniable, yet many overlook important details. Size, material, and mesh type play significant roles in performance. Neglecting these factors can lead to complications down the line.

Remember, not all Woven Wire Mesh is created equal. A mesh ideal for one application may fail in another. It's essential to carefully evaluate your project's requirements. Taking shortcuts in this decision can have lasting repercussions. Aim for a thoughtful selection process to ensure the best outcome.

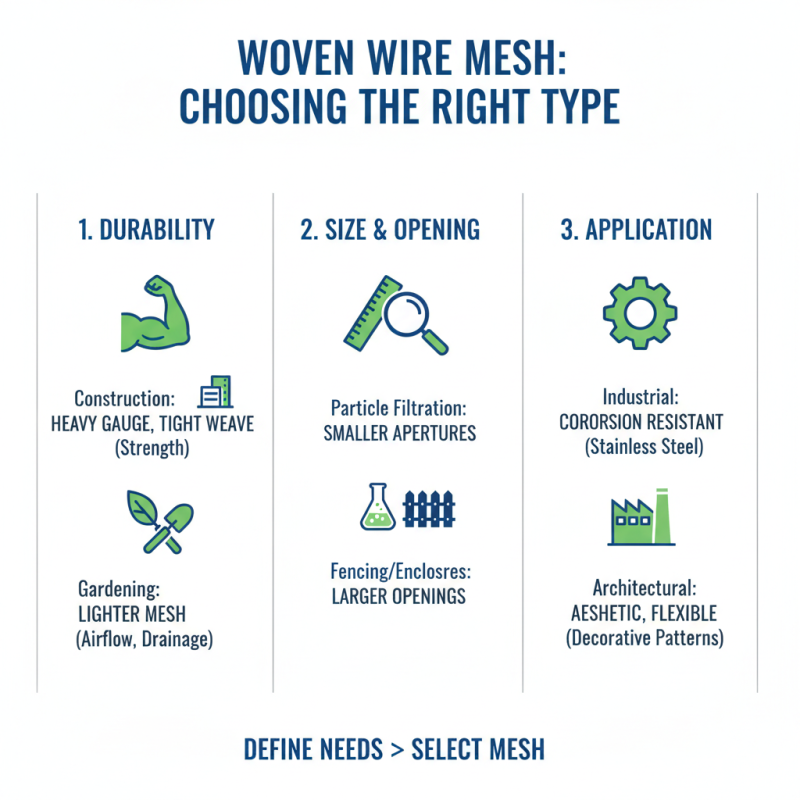

When choosing woven wire mesh, understanding its types and applications is crucial. Woven wire mesh is used in various industries, including construction, agriculture, and manufacturing. Different mesh types offer unique benefits. For instance, fine mesh is ideal for filtration applications, while heavier gauges are better suited for security fencing.

A report by the Wire Mesh Manufacturers Association indicates that the construction industry accounts for over 35% of woven wire mesh usage. This is due to its durability and versatility. In agriculture, it is often used for fencing and animal containment. Choosing the right type depends on both the intended use and environment.

Tips: Always consider the mesh opening size. Too small may restrict airflow, while too large may fail to keep pests away. Additionally, gauge thickness plays a significant role in the strength and durability of the mesh. Evaluate your project's specific demands carefully. Remember, selecting the wrong mesh can lead to ineffective outcomes and unnecessary costs.

When selecting the right woven wire mesh, evaluating wire diameter and mesh opening sizes is crucial. The wire diameter directly influences strength and durability. Thicker wires provide more robustness, while thinner wires may allow for greater flexibility. For instance, a 0.5 mm wire might work well for lightweight applications. However, it may not stand up to high stress or heavy loads.

Mesh opening sizes determine what can pass through the mesh. Smaller openings are ideal for retaining tiny particles. This is important for projects such as sand filtration. On the other hand, larger openings are better for air circulation and drainage. A mesh with 1-inch openings serves well in applications needing better airflow, yet it won't contain smaller debris effectively.

It's important to balance between these two factors. Sometimes, opting for a thicker wire with larger openings might seem efficient, but it could compromise the mesh’s intended purpose. Reflecting on specific project requirements is essential. Test different combinations to find a suitable solution for your needs. Finding the right match may take time and experimentation.

When selecting woven wire mesh, material choice is crucial for durability. Some options resist wear better than others. Stainless steel is popular due to its toughness. It withstands heavy use and corrosion. However, it can be expensive, and not everyone has that budget. Alternatives like galvanized steel offer a cost-effective solution, but may not last as long in harsh environments.

Plastic mesh is another option. It is lightweight and resistant to rust. This type suits projects needing flexibility. But it can suffer from UV damage in sunlight. Users should consider where their mesh will be used. Durability matters, but so does cost.

Many people overlook the benefits of woven wire mesh's opening size. Large openings allow airflow but let through debris. Small openings trap more, which can be a drawback. Assessing your specific needs is vital. Think about how often the mesh will be exposed to elements. This reflection can guide you to the best choice for your project.

| Material Type | Durability Rating | Corrosion Resistance | Common Applications |

|---|---|---|---|

| Stainless Steel | High | Excellent | Food processing, marine environments |

| Galvanized Steel | Moderate | Good | Construction, fencing |

| Plastic Coated | Moderate | Good | Outdoor applications, gardening |

| Copper | Low | Poor | Electrical applications, art |

Choosing the right woven wire mesh begins with understanding your project's specific needs. What are the key requirements? Are you focused on durability, size, or application? For instance, in construction, strength might be your top priority. This often means heavier gauge wire and tighter weave. In contrast, for gardening projects, a lighter mesh may suffice, allowing for better airflow and soil drainage.

Identifying the standards required for your project is equally crucial. Local regulations may dictate certain specifications. Ignoring this could lead to delays or rework. Sometimes, specifications may seem tedious. Yet, they ensure safety and performance. Consulting with industry guidelines can ease this process. Still, feel free to question the norms and explore alternative options. Each project is unique, and flexibility can lead to innovative solutions. Keep in mind that your choices may evolve as you gather more information. An open mind can enhance your decision-making process.

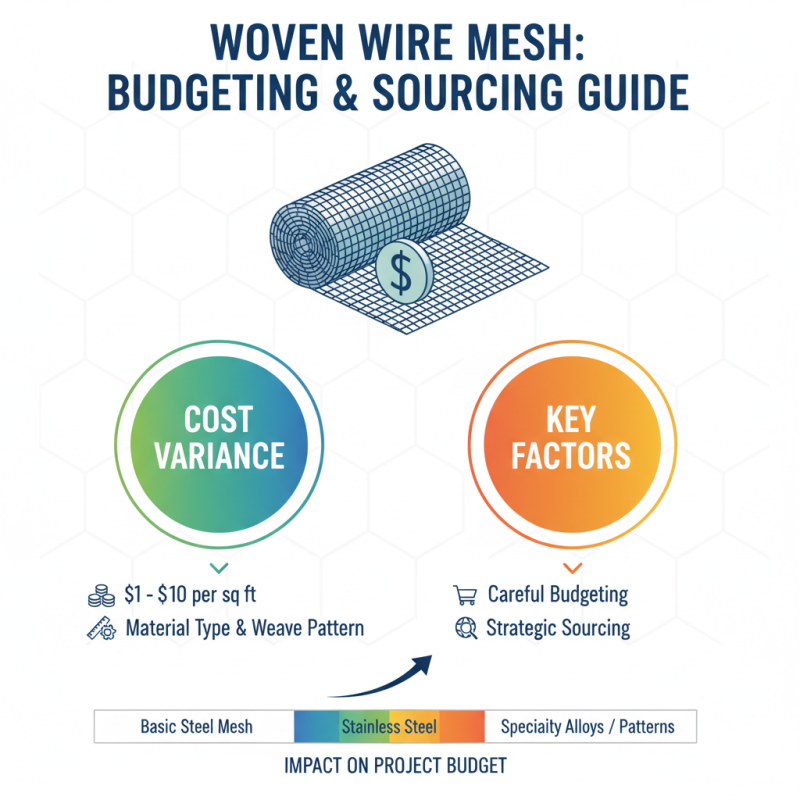

Choosing woven wire mesh requires careful budgeting and sourcing. The cost of these materials can vary significantly. According to industry reports, woven wire mesh products can range from $1 to $10 per square foot, dependent on material type and weave pattern. This variance can greatly impact your overall project budget.

Tip: Always request multiple quotes. This allows for comparison and potential savings. Sourcing from local suppliers may provide lower shipping costs, but online suppliers might offer better deals. Understanding your project needs will streamline this process.

When budgeting, consider not just the material costs. Installation, maintenance, and potential customizations can add to your expenses. Research indicates that many projects exceed their budgets by 20% due to unforseen costs. Keeping a flexible budget can help manage these surprises.

Tip: Allocate a contingency fund for unexpected expenses. This can help you avoid financial strain during your project. Remember, choosing the right woven wire mesh is not only about cost. Quality should also play a major role in your decision-making process. Don't overlook factors like durability and application-specific requirements.