In today's industrial landscape, efficiency and durability are crucial. Businesses often seek components that enhance productivity and reduce downtime. The Wire Mesh Belt emerges as a standout choice. Its design offers versatility across various industries, from food processing to automotive manufacturing.

Wire Mesh Belts are known for their strength and resilience. They can withstand high temperatures and corrosive materials. This durability helps prevent frequent replacements. Instead, companies can focus on their core operations. Moreover, the open design allows for excellent airflow. This feature is particularly beneficial in cooling and drying applications.

However, like any product, Wire Mesh Belts have their challenges. Ensuring proper maintenance is essential to maximize their lifespan. Some might overlook the need for regular cleaning. If neglected, efficiency can suffer. Recognizing these aspects is key to making an informed decision. Embracing Wire Mesh Belts could be a pivotal step for businesses aiming for long-term success.

Wire mesh belts are becoming a popular choice in various industrial settings. Their design offers unique advantages over traditional conveyor systems. They provide excellent airflow, which is crucial for cooling and drying processes. Additionally, these belts are easy to clean and maintain, helping to reduce downtime and improve efficiency.

The durability of wire mesh belts is another significant benefit. They can withstand high temperatures and harsh chemicals, making them ideal for food processing and metalworking applications. However, not all wire mesh belts are created equal. Some may not perform well under heavy loads. It’s important to assess the specific needs of your operation.

Versatility also sets wire mesh belts apart. They can be customized in size and shape to fit different machinery. This adaptability means they can solve unique challenges in any production line. Yet, achieving the right balance between load capacity and flexibility may require careful planning. Understanding the specific environment and product flow can lead to better outcomes.

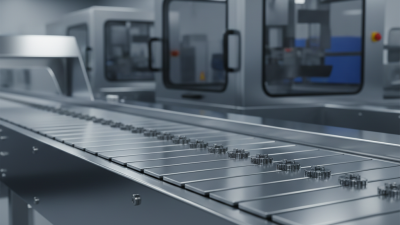

Wire mesh belts come in various types, each tailored for specific industrial applications. For instance, flat wire mesh belts are widely used in food processing. Their open design allows for efficient drainage and air circulation, essential for drying and cooling food products. These belts are ideal for bakeries and snack food operations.

In contrast, spiral wire mesh belts are commonly used for chilling and freezing. These belts move products through chilling tunnels smoothly. Their spiral design maximizes space and enhances cooling efficiency. Moreover, modular wire mesh belts are flexible and can be customized for various industries. They are easy to maintain and replace, providing a cost-effective solution for many operations.

Choosing the right belt is crucial. It can affect overall productivity and maintenance needs. Sometimes, companies overlook the specifics of their operations. This can lead to inefficiencies. Not every belt fits every need. Understanding the diverse types and their applications is vital for industrial success.

When selecting wire mesh belts for industrial purposes, several factors come into play. Durability is crucial. You want a belt that can withstand heavy loads and harsh conditions. Consider the material and design. Stainless steel is a popular choice due to its resistance to corrosion. It’s vital for food processing environments where hygiene is paramount.

Another factor is temperature tolerance. Some processes require belts that can endure extreme heat or cold. Ensure the belt matches your operational needs. Testing is key. New designs may need adjustments for optimal performance.

**Tip:** Evaluate the specific application before purchasing. This saves time and avoids costly errors.

Flexibility and maintenance should also be considered. A belt that bends easily is helpful in tight spaces. However, be aware that complex designs may complicate repairs. Simple is often better in logistics.

**Tip:** Schedule regular maintenance checks. This extends the lifespan of the belt and maintains efficiency.

Ultimately, the right wire mesh belt can enhance productivity. Choosing blindly can lead to frustration and inefficiency. Take the time to analyze your needs and requirements carefully.

Wire mesh belts have become essential in various industrial processes. Their maintenance and longevity are crucial for efficient operation. According to industry reports, these belts can last anywhere from 10 to 20 years with proper care. This durability makes them a cost-effective solution for many manufacturers.

Regular maintenance is vital. Routine inspections can help identify wear and tear early. It is common for users to overlook minor damages. However, even small issues can lead to larger problems. Belts may break or malfunction without warning. Industry experts recommend checking tension and alignment frequently. These steps may prevent costly downtimes.

Another consideration is cleaning. Wire mesh belts can accumulate debris and residue. A quick wash can enhance their performance. Reports suggest that dirty belts decrease efficiency by up to 15%. Implementing a cleaning schedule could mitigate this loss. Investing in maintenance pays off over time. Ignoring it can lead to diminished lifespan and increased costs. Balancing performance with upkeep is a challenge many face.

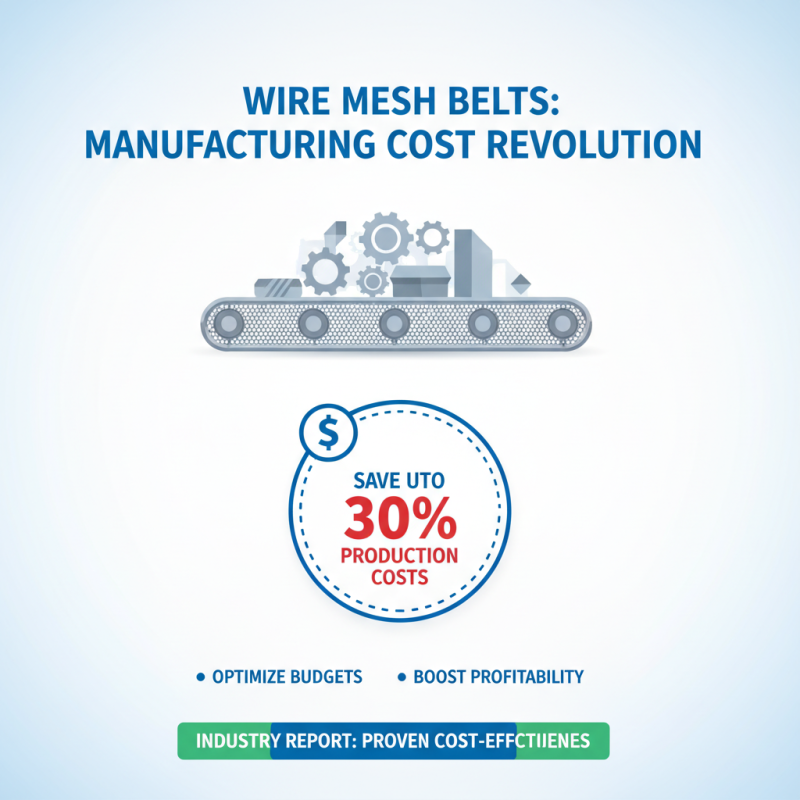

Wire mesh belts are increasingly popular in various manufacturing processes. Their cost-effectiveness cannot be overstated. A recent industry report highlights that these belts can reduce production costs by up to 30%. This number is significant for companies looking to optimize their budgets.

The durability of wire mesh belts contributes to their efficiency. They offer excellent resistance to wear and tear, reducing replacement frequency. According to data from manufacturing studies, these belts can last up to five times longer than traditional materials. This longevity translates into savings on maintenance and replacement costs.

However, not every application suits wire mesh belts. Some industries may find them less efficient for specific tasks. It's essential to assess the balance between cost and performance. Companies should evaluate the total cost of ownership, considering both initial investment and long-term expenses. This analysis reveals the true value of choosing wire mesh belts for their needs.