Choosing the right Wire Mesh can seem overwhelming. Various types exist, each designed for specific uses. Understanding these differences is crucial for successful project outcomes.

Wire Mesh is used in many applications, from construction to gardening. Some options provide strength, while others focus on flexibility. Selecting the best one depends on factors like material, gauge, and mesh size.

Many people underestimate the importance of proper selection. A mismatch can lead to safety issues or reduced efficiency. Take the time to research and consider your unique project needs. Your choice in Wire Mesh can make a significant difference.

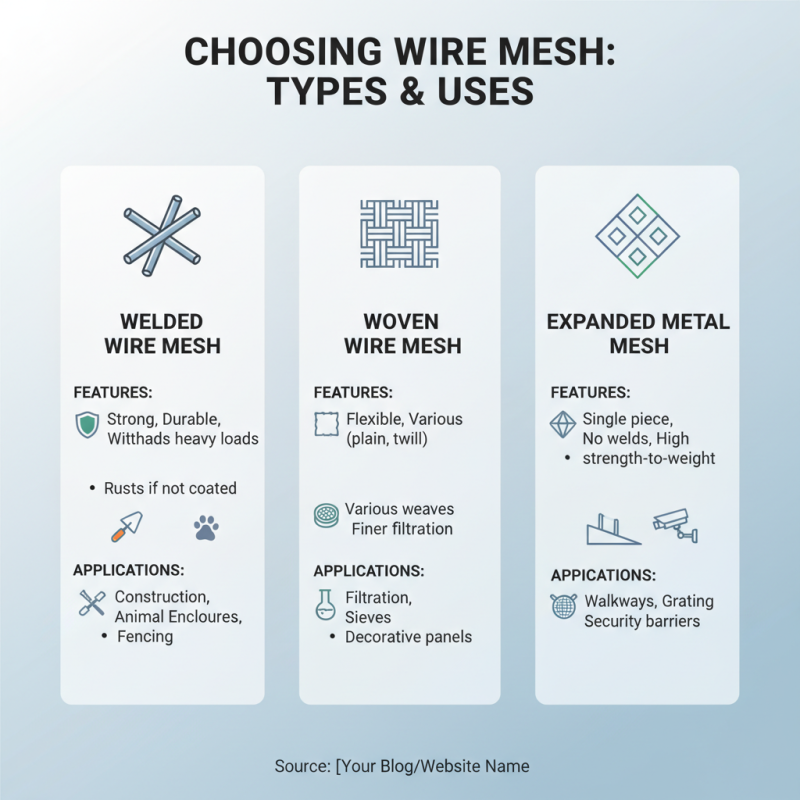

When choosing wire mesh for your project, understanding the different types is crucial. There are several options available, each with its unique features and applications. For instance, welded wire mesh is strong and durable. It's often used in construction and animal enclosures. This type can handle heavy loads; however, it may rust if not properly coated.

Another popular choice is woven wire mesh. This option provides flexibility and is available in various sizes. It's commonly used in fencing and shelving. You might appreciate its aesthetic appeal, but be cautious of potential sagging under weight. Expanded metal mesh, on the other hand, is made by cutting and stretching sheets of metal. It offers strength and ventilation, making it suitable for walkways and safety screens.

Sometimes, you may find it hard to decide which type to use. Each option fits different needs. Balancing strength and aesthetics can be tricky. Be mindful of your specific project requirements, and consider consulting with experts when in doubt.

Choosing the right wire mesh for your project can be challenging. Start by considering the material. Different projects require specific materials, such as stainless steel or galvanized options. Think about strength, corrosion resistance, and durability. These factors will impact the overall longevity of your mesh.

Next, consider the mesh's opening size. Smaller openings may provide better security or filtration. Larger openings can offer better airflow and visibility. However, the choice depends largely on your project's specific needs. Sometimes, compromises must be made. Finding the balance is crucial.

Finally, pay attention to the wire diameter. Thicker wires are stronger but may be heavier and more difficult to work with. Thin wires are easier to handle but might lack the necessary strength for some applications. Reflect on these details. Each factor plays a role in the mesh's effectiveness. Don't rush the decision. Take your time to ensure the wire mesh suits your needs perfectly.

When choosing wire mesh, understanding specifications is key. Wire mesh varies widely in material, gauge, and coating. A recent industry report indicates that stainless steel wire mesh is gaining popularity due to its durability and corrosion resistance. It's essential to consider these factors as they impact both performance and lifespan.

Mesh specifications include the opening size, which can range from very fine to several inches. For instance, a mesh with smaller openings is ideal for filtration. However, it may be less suitable for projects requiring strong structural support. Reports suggest that a thickness of 0.25 inches or more is recommended for rigidity. Yet, many overlook these details, relying solely on the appearance instead.

Another critical aspect is the wire gauge. A lower gauge number indicates thicker wire, resulting in stronger mesh. Many projects fail because of improper wire size selection. Using a higher gauge may save costs initially but can lead to failure under stress. Reflecting on project needs is essential. Don't rush this step. Choose wisely to ensure long-term success.

Choosing the right wire mesh for your project requires careful consideration of specific applications. Different projects demand unique characteristics from wire mesh. For example, fencing requires durability and resistance to rust. A heavier gauge may be necessary to ensure longevity in outdoor settings.

In industrial applications, wire mesh often serves as a safety barrier. Here, mesh openings play a crucial role. Smaller openings can prevent objects from passing through, but they may limit visibility. On the other hand, larger openings offer better airflow and visibility but may not provide adequate safety for small items. It's a balancing act requiring thoughtful assessment of each project's needs.

Architectural designs also utilize wire mesh in creative ways. Here, aesthetics matter just as much as functionality. Choosing a mesh with the right finish is important. A shiny finish may look modern, but it could reflect unwanted light in certain areas. Each decision influences the overall impact of the project. It’s essential to weigh these variables and ensure the final selection aligns with your vision.

| Application | Wire Diameter (mm) | Mesh Opening (mm) | Material | Common Uses |

|---|---|---|---|---|

| Construction | 3.0 | 50 | Steel | Reinforcement, formwork |

| Agriculture | 1.5 | 25 | Galvanized Steel | Fencing, crop protection |

| Filtration | 0.5 | 10 | Stainless Steel | Water treatment, air filters |

| Safety | 2.0 | 15 | Plastic | Guard rails, enclosures |

Wire mesh is a versatile material, useful in various projects. When it comes to installation, there are some key tips to keep in mind. First, always check the area where you will install the mesh. Is it level and stable? A solid foundation makes all the difference. Make sure to measure twice before cutting. This prevents waste and extra work.

For maintenance, inspect the wire mesh regularly. Look for signs of rust or damage. If you spot issues, address them immediately. Simple repairs can extend the life of your mesh. Sometimes, users overlook this step, thinking everything is fine. A quick touch-up with protective paint can work wonders.

Remember to secure the wire mesh tightly during installation. Loose fittings may lead to sagging or deformities over time. It's easy to rush this step. Don't let the eagerness to complete the project affect the quality. A little time spent on proper installation pays off in long-term performance.