Choosing the right Food Conveyor Belt can significantly impact efficiency in production lines. According to a recent industry report, more than 70% of food manufacturers face challenges related to material handling. A conveyor belt is not just about transportation; it affects safety, hygiene, and productivity. Many companies overlook the importance of selecting the appropriate belt for their specific needs.

Consider the variety of food types processed. Different products require different belt materials, such as plastic, metal, or rubber. Some belts can withstand high temperatures, while others resist chemical exposure. This complexity can lead to mistakes if not addressed properly. In a recent survey, 65% of manufacturers reported complications from using non-specialized conveyor belts.

Investing time in choosing the right Food Conveyor Belt is crucial. It's not merely a mechanical decision; it touches on regulatory compliance and product quality. Yet, many organizations still default to cheaper options, only to regret their choices later. This highlights the importance of thorough research and careful selection. The impact of a poorly chosen conveyor belt can be costly and may hinder production.

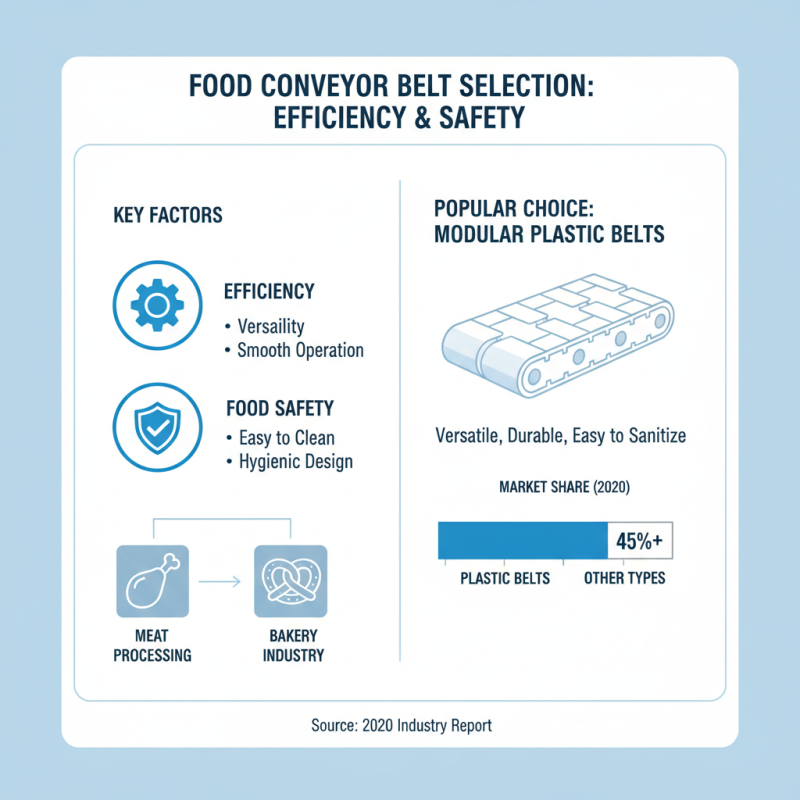

Choosing the right food conveyor belt is crucial for efficiency and food safety. Various types of conveyor belts exist, each designed for specific applications. For instance, modular plastic belts are versatile and easy to clean. They are often used in meat processing and bakery industries. A 2020 industry report noted that plastic belts comprised over 45% of the market share due to their durability.

On the other hand, rubber belts are more suited for heavy loads. They can transport products at steep angles. However, they may require more maintenance, which can lead to increased downtime. An analysis indicated that nearly 30% of production delays stem from conveyor malfunctions, highlighting the need for appropriate belt selection.

Wire mesh belts are another option for high-temperature environments, especially in frying and baking processes. Their design allows for optimal airflow. However, they might not provide sufficient support for smaller items, which can lead to product loss. Balancing these factors is essential for maximizing production efficiency and minimizing waste.

Choosing the right food conveyor belt is crucial for maintaining efficiency and safety in food processing. One key factor is material selection. Many industries favor belts made from thermoplastics due to their durability and resistance to high temperatures. According to a report from the Food Processing Manufacturers Association, over 45% of companies have experienced belt failure due to using unsuitable materials. This can lead to costly downtime and safety hazards.

Another essential consideration is the belt's design. A well-designed belt can prevent product contamination. Manufacturers should ensure that the belt has appropriate surface textures to minimize slippage and retention of food particles. However, not all designs are effective for all products. In fact, a study indicated that poorly designed belts can lead to up to 30% more spoilage in sensitive food items. Regular assessments of belt performance can help identify these weaknesses.

Finally, compliance with safety standards is non-negotiable. Food conveyor belts must meet FDA regulations for materials in food contact. Yet, a survey revealed that 27% of plants do not keep up with regulatory changes, increasing their risk of violations. Monitoring compliance can seem overwhelming. However, it is crucial for both safety and quality control. Selecting the right conveyor belt is complex and requires careful thought.

This chart illustrates the importance of various factors when selecting a food conveyor belt. Each factor is rated on a scale of 1 to 10, with 'Hygiene Standards' being the most critical consideration at a rating of 10, followed by 'Material Durability' and 'Ease of Cleaning.'

When choosing a food conveyor belt, assessing materials and durability is crucial. Different materials react differently to various environments. For instance, stainless steel is often preferred for its corrosion resistance and durability. According to industry reports, about 40% of food processors prioritize durable materials to reduce operational downtime.

**Tip:** Always verify material compliance with food safety standards. This ensures safety and meets regulatory requirements. Failure to do so can lead to contamination risks. Many factories face recalls due to inadequate material checks.

Durability affects the long-term cost of ownership. A more durable belt may have a higher upfront cost but can save money in replacements. An analysis found that belts with a lifespan of over five years can lower operational costs by up to 30%. Still, even the best materials can be vulnerable to wear and tear. Regular inspections are often neglected, yet they are essential for maintaining performance.

**Tip:** Consider environmental factors. Extreme temperatures and chemical exposure can reduce belt life. Engage employees in routine inspections and encourage feedback on material performance. Mistakes often happen when staff is not involved in the decision-making process. This leads to dissatisfaction and poor outcomes.

| Material Type | Durability Rating | Temperature Range (°C) | Food Safety Certification | Cost per Meter |

|---|---|---|---|---|

| PVC | Moderate | -10 to 80 | FDA Approved | $15 |

| Polyurethane | High | -20 to 100 | FDA Approved | $20 |

| Stainless Steel | Very High | -40 to 200 | FDA Approved | $50 |

| Rubber | Moderate | -10 to 70 | FDA Approved | $18 |

| Nylon | High | -30 to 90 | FDA Approved | $22 |

When selecting a food conveyor belt, hygiene and sanitation are paramount. The material of the belt must resist bacteria and be easy to clean.

Durable, non-porous surfaces reduce the risk of contamination. Check for seams and joints. These areas can trap residue, making thorough cleaning difficult.

Consider belts with smooth finishes. They simplify maintenance and improve sanitation protocols.

Certifications are critical in evaluating hygiene standards. Look for belts that meet food safety regulations. They may have specific ratings for food contact safety.

This is essential, especially in the food industry. However, even certified products can fail without proper care. Regular inspections are necessary. Reports can guide the ongoing standards of your conveyor equipment.

A less visible aspect is the storage and maintenance of belts. Dust and moisture can accumulate. These elements create a breeding ground for pathogens. Review how belts are stored when not in use.

Insufficient humidity control can lead to microbial growth. Always think about the entire lifecycle of the conveyor belt. This includes its sanitation needs from installation to daily operations.

Choosing the right size and configuration for a food conveyor belt is crucial. Size affects productivity and efficiency. A study by the Food Industry Association revealed that 70% of food manufacturers faced bottlenecks due to improperly sized conveyor systems. Understanding your operational space helps avoid these pitfalls.

Consider your product characteristics. For instance, fragile items need gentler handling. A narrow belt may suit smaller products, while wider belts can accommodate bulkier goods. The layout of your facility matters too. A linear configuration saves space, but a flexible layout might improve workflow. Aligning the belt’s design with your production needs can enhance efficiency.

Regular assessments of your conveyor systems are essential. Some companies overlook the importance of periodic evaluations. Up to 30% of businesses report issues due to neglecting maintenance. Ensure you are not part of that statistic. Adjust configurations based on changes in production volume or product type. Challenging yourself to innovate might lead to better outcomes.