When it comes to optimizing production processes, the choice of a Wire Conveyor Belt can make a significant difference. According to industry expert John Smith, who has over 20 years of experience in material handling solutions, "Selecting the right Wire Conveyor Belt is crucial not only for efficiency but also for ensuring product integrity throughout the manufacturing cycle." With a wide variety of materials, designs, and specifications available, making the right decision can feel overwhelming.

Understanding the unique requirements of your operation is key. Factors such as load capacity, temperature resistance, and specific application needs play a vital role in the selection process. Smith emphasizes that "Investing time in choosing the correct Wire Conveyor Belt can lead to substantial long-term savings and improved productivity." With this insight, it is clear that a strategic approach to selecting a Wire Conveyor Belt is essential for any business looking to enhance their efficiency and reliability in their production lines.

When it comes to selecting the right wire conveyor belt, understanding the different types available is crucial. Wire conveyor belts can be divided into several categories, including spiral, flat wire, and welded wire belts, each designed for specific applications and operational environments. According to a report by Freedonia Group, the aggregate demand for conveyor belts in the United States alone is projected to reach $4.3 billion by 2026, highlighting the growth and variety of applications for these systems across industries such as food processing, packaging, and automotive manufacturing.

Spiral wire belts, known for their spiral design, provide excellent airflow and drainage, making them ideal for applications involving baking or cooling processes. Flat wire belts, on the other hand, offer a flat surface which is beneficial for supporting heavy loads, while still maintaining a lightweight structure. These belts are particularly effective in applications where precision and high-speed movement are required. Welded wire belts typically provide enhanced strength and durability, making them suitable for more demanding tasks. Industry studies indicate that choosing the appropriate belt type can enhance system efficiency by over 15%, emphasizing the importance of understanding the options available to best meet operational needs.

| Type of Wire Conveyor Belt | Best Use Cases | Advantages | Considerations |

|---|---|---|---|

| Flat Wire Belt | Food processing, packaging | Easy to clean, good air circulation | Can be less durable under heavy loads |

| Fiberglass Wire Belt | High-temperature applications | Heat resistant, strong | Higher cost, brittle at low temps |

| Spiral Wire Belt | Baking and cooling | Efficient heat transfer, continuous flow | More complex maintenance |

| Welded Wire Belt | Material handling, automotive | High load capacity, durability | May require lubrication |

| Chain Link Wire Belt | Heavy-duty applications | Strength and versatility | Heavy and may limit flexibility |

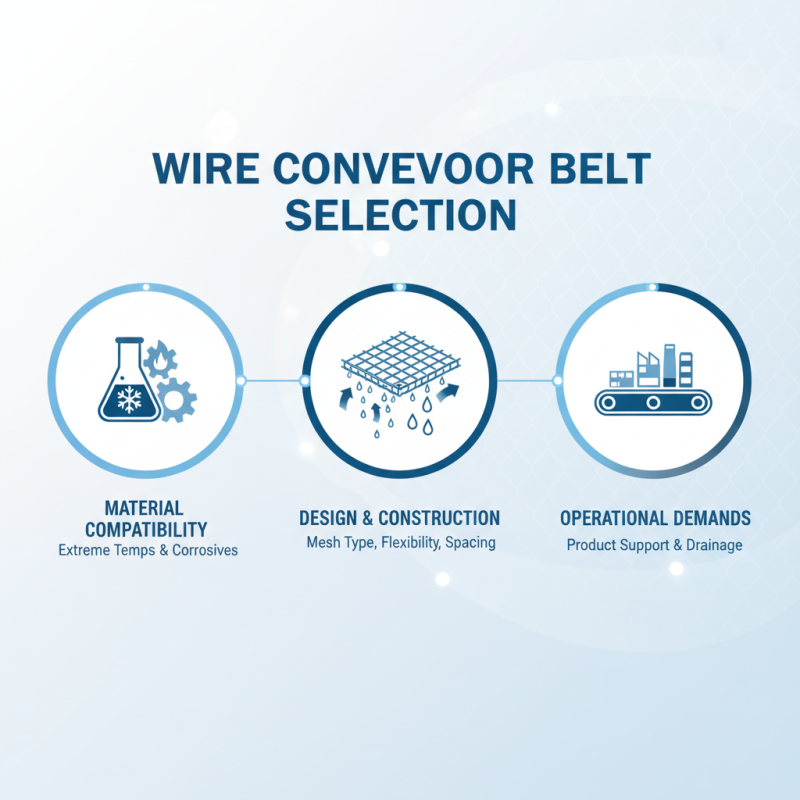

When selecting a wire conveyor belt, several key factors must be considered to ensure the chosen belt meets your operational demands effectively. First, assess the material compatibility; the belt material should be compatible with the products it will transport, especially in environments with extreme temperatures or corrosive substances. Additionally, the belt’s design and construction play a crucial role in its performance. Consider the type of wire mesh, its flexibility, and the spacing between wires, as these factors influence airflow, drainage, and the overall support the belt provides.

Another essential factor is the load capacity and weight distribution of the belt. Understanding the maximum load it will bear is crucial to prevent premature wear or failure during operations. Moreover, the belt width and length should be carefully measured to fit the intended application and workspace effectively. Lastly, maintenance requirements should not be overlooked—opt for a belt that balances durability with ease of upkeep to minimize downtime and enhance operational efficiency. These considerations will guide you to the right wire conveyor belt tailored to your specific needs.

When selecting the right wire conveyor belt for your needs, evaluating material compatibility is crucial for ensuring optimal performance and longevity. According to a report by the Conveyor Equipment Manufacturers Association (CEMA), improper material selection can lead to increased wear and tear, resulting in costly downtime and maintenance. It is imperative to consider the type of materials being transported, their temperatures, and any potential chemical exposure that might occur during operation. For example, belts designed to withstand extreme temperatures are essential in industries like metal processing, where belts may be exposed to hot ingots.

Additionally, the compatibility of the conveyor belt material with the transported goods can significantly affect efficiency. A study conducted by the International Journal of Industrial Engineering and Management indicates that mismatched materials can lead to product damage and increased friction, ultimately affecting throughput rates.

When evaluating wire materials—whether stainless steel, carbon steel, or plastic—one must consider factors such as corrosion resistance, strength-to-weight ratio, and surface finishing. The right choice will not only enhance system reliability but also optimize the overall lifecycle cost of the conveyor system, aligning with broader operational goals and sustainability practices in the industry.

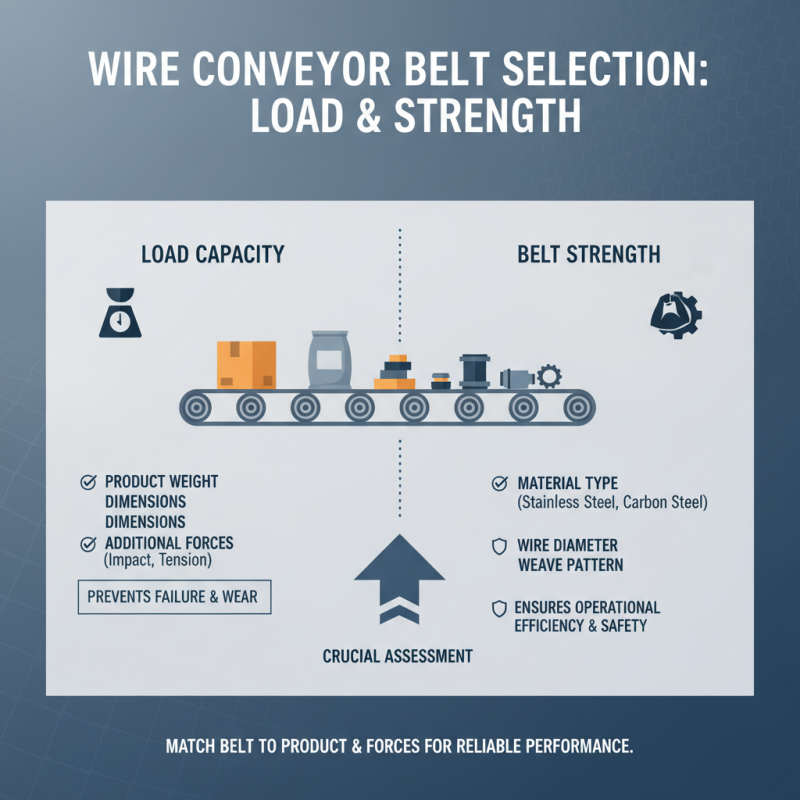

When selecting a wire conveyor belt, understanding load capacity and belt strength requirements is crucial for ensuring operational efficiency and safety. The load capacity of a conveyor belt defines how much weight it can carry without compromising its integrity. It is essential to assess the weight of the products being transported, including their dimensions and any additional forces that may act upon the belt during operation. This assessment allows for the selection of a belt that can handle the specific application without risk of failure or excessive wear.

One key tip is to consult with experts in material handling to identify the best belt specifications based on your load requirements. They can provide insights into both static and dynamic load capacities, which help in making a more informed choice. Additionally, considering the strength of the materials used in manufacturing the belt is vital. High-strength materials can offer better performance and longevity, especially in demanding environments.

Another important consideration is the belt's tensile strength, which indicates its resistance to stretching and deformation under load. Choosing a belt with adequate tensile strength prevents sagging and improves the overall reliability of the conveyor system. Regularly evaluating these factors, along with the operational conditions, will ensure that your wire conveyor belt meets the demands of your specific application effectively.

When selecting a wire conveyor belt, durability and maintenance are critical factors that significantly impact its lifespan and performance. According to a report by the Material Handling Industry of America (MHIA), improper maintenance can decrease the operational efficiency of conveyor systems by up to 30%. Regular maintenance, including inspecting for wear and replacing damaged sections, can extend the belt's life and reduce the risk of operational disruptions. Ensuring the belt is aligned correctly can also prevent strain and misalignment issues, contributing to a longer service life.

Moreover, the choice of materials used in wire conveyor belts plays an essential role in their durability. A study by Dynamic Research Group highlights that belts made from high-grade stainless steel can withstand extreme temperatures and corrosive environments, leading to significant cost savings in replacements and repairs. Additionally, the incorporation of advanced coatings can enhance resistance against abrasion, which is crucial in high-traffic industrial settings. By prioritizing maintenance practices and selecting robust materials, businesses can significantly enhance the longevity of their conveyor systems, thus optimizing productivity and reducing downtime.