Industrial belting plays a crucial role in various manufacturing and processing industries, serving as the backbone of many mechanical systems. From transporting materials to driving machinery, the right type of belting can significantly enhance efficiency and productivity. This comprehensive guide explores the diverse world of industrial belting, focusing on its various types, materials, and specific applications across multiple sectors.

Understanding industrial belting is essential for manufacturers looking to optimize their operational processes. The selection of appropriate belts not only influences the performance of machinery but also impacts maintenance costs, energy consumption, and overall output. In this introduction to industrial belting, we will delve into the fundamental concepts, highlighting how different types of belts, such as flat belts, V-belts, and modular belts, are tailored to meet the unique demands of different applications. Join us as we navigate through the intricacies of industrial belting and uncover the best practices for ensuring seamless operations in the industrial landscape.

Industrial belting plays a crucial role in numerous manufacturing processes, serving as a vital link in the movement of materials across various operations. Defined as a flexible loop of material used to transport items, industrial belts are essential components in conveyor systems, machinery, and other automated solutions. According to a recent industry report by Grand View Research, the global industrial belts market is projected to reach USD 20 billion by 2025, driven by the increasing demand for efficiency in production lines.

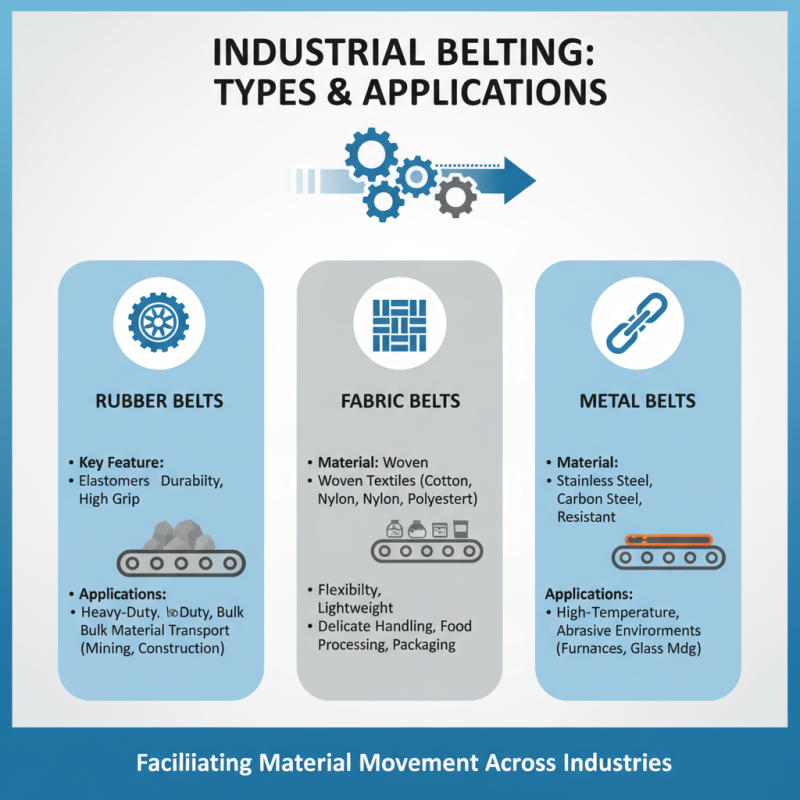

Understanding the importance of industrial belting is essential for ensuring optimal performance within manufacturing environments. Different types of belts, such as rubber, modular plastic, and leather belts, each serve unique functions that cater to specific industry needs. For instance, rubber belts excel in heavy-duty applications due to their durability, while modular plastic belts offer flexibility in food processing environments—adapting to various shapes and sizes.

**Tip:** Regular maintenance of these belts is crucial to prolong their lifespan. Invest in routine inspections and cleaning practices to identify wear and prevent breakdowns. Additionally, choosing the right type of belt for your specific application can significantly enhance productivity and reduce operational costs.

Industrial belting plays a crucial role in various sectors, facilitating the movement of materials and products within manufacturing processes. The key types of industrial belts are commonly categorized based on the materials they are made from, such as rubber, fabric, and metal. Each type presents unique design features suited for specific applications. For instance, rubber belts are known for their durability and grip, making them ideal for heavy-duty operations, while fabric belts offer flexibility and lightweight solutions for more delicate tasks.

When selecting industrial belts, consider the operational environment and load requirements. High-temperature or chemical exposure may necessitate specialized materials that can withstand harsh conditions. Additionally, always review the belt's design for features like cogging or perforations, which might enhance performance and efficiency.

**Tips:** Regular maintenance is essential for prolonging the life of industrial belts. Inspect belts frequently for signs of wear and tear, and replace them as needed to avoid unexpected downtimes. Moreover, ensure proper tension is applied, as both loose and overly tight belts can lead to significant operational issues.

Industrial belting is a critical component used across various sectors, providing essential functionality for numerous applications. Its importance spans industries such as manufacturing, food processing, and logistics, where the need for reliable transportation of materials and products is paramount. According to recent data, the global specialty carbon black market is projected to grow significantly, reflecting a broader trend of increasing investment in industrial components that enhance operational efficiency. This growth is indicative of the rising demand for high-quality industrial belts, which help maximize productivity while ensuring safety and reliability.

Tips: When selecting industrial belting, consider the specific requirements of your application, including temperature, load capacity, and environmental conditions. Proper maintenance and regular inspections can significantly extend the lifespan of your belting systems.

With ongoing investments in local production and innovation, companies are adapting to meet the evolving needs of the market. This includes focusing on sustainable materials and practices that cater to the growing demand for responsible manufacturing. Understanding the unique applications of industrial belting will enable industries to make informed decisions, ensuring they choose the most suitable solutions tailored to their operational demands.

When evaluating industrial belting, performance metrics play a critical role in determining the durability and efficiency of belts. Key factors to consider include tensile strength, abrasion resistance, and the temperature range in which the belts can operate effectively. Tensile strength refers to the maximum amount of tensile (pulling) stress a belt can withstand before breaking, making it essential for applications with heavy loads. A belt with high tensile strength not only prolongs its lifespan but also minimizes operational disruptions.

Abrasion resistance is another vital metric, as it measures how well a belt can withstand wear and tear over time. Industrial environments often expose belts to harsh conditions, including contact with abrasive materials. A belt with superior abrasion resistance can maintain its performance and integrity even in demanding settings. Additionally, evaluating operational efficiency often entails analyzing friction coefficients and energy consumption during use. Low friction implies less energy loss, leading to more efficient material handling processes. By focusing on these performance metrics, businesses can choose the appropriate belts that align with their specific operational needs, thereby enhancing overall productivity.

As we look toward 2025, the future of industrial belting is heavily influenced by emerging trends in waste management, particularly through innovations in sustainability practices. One significant change is the shift toward decentralized systems that reduce carbon footprints and enhance efficiency. According to a recent industry report, companies adopting decentralized waste management solutions can achieve up to 30% lower operational costs and a significant reduction in waste generated, highlighting the economic and environmental benefits of these systems.

Intelligent automation is another key trend reshaping industrial processes. Automated systems, such as AI-driven sorting mechanisms, enable more precise waste separation, increasing the recycling rates significantly. Studies indicate that facilities implementing intelligent automation can see a 15-20% improvement in operational efficiency and resource recovery rates. This integration not only enhances productivity but also aligns with global sustainability goals, reducing reliance on landfills and fostering a circular economy.

**Tips:** 1. Invest in smart technologies that enhance your waste management capabilities. Look for automated systems that offer predictive analytics to streamline operations. 2. Consider partnering with companies focusing on sustainable practices to foster collaboration and innovation within the industry. By leveraging these trends, businesses can enhance their competitiveness while contributing to a more sustainable future.

| Belt Type | Material | Common Uses | Sustainability Features | Future Trends |

|---|---|---|---|---|

| Flat Belts | Polyester, Nylon | Material handling, Conveyor systems | Recycled materials, Biodegradable options | Smart technology integration, Increased longevity |

| V-Belts | Rubber, Polyurethane | Automotive machinery, Agricultural equipment | Longer wear, Sustainable sourcing | Energy-efficient designs, Custom manufacturing |

| Timing Belts | Rubber, Neoprene | Automotive, Robotics | Recyclable options, Low environmental impact | Advanced simulations, DNA-based materials |

| Modular Belts | Plastic, Polypropylene | Food processing, Packaging | Reusable modules, Waste reduction | Customization technologies, Increased health safety |