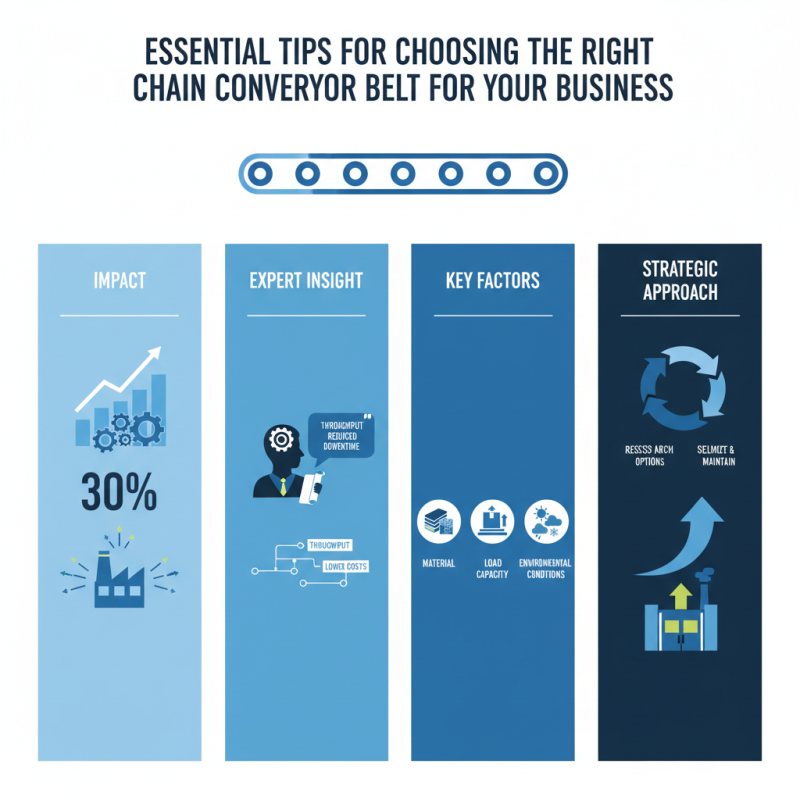

When selecting a Chain Conveyor Belt for your business, making an informed decision is critical, as it can significantly impact your operational efficiency and productivity. According to recent industry reports by the Conveyor Equipment Manufacturers Association (CEMA), the use of specialized conveyor systems has led to a productivity increase of up to 30% in manufacturing settings. With such compelling statistics, understanding the intricacies involved in choosing the right chain conveyor belt becomes essential for any business aiming to enhance its logistics and production processes.

Expert insights also highlight the importance of this decision. Dr. James Carter, a leading authority in industrial conveyor systems, emphasizes, "The right chain conveyor belt not only improves throughput but also reduces maintenance costs and downtime." Businesses must consider various factors such as the material, load capacity, and environmental conditions when selecting the appropriate chain conveyor belt to ensure optimal performance. By taking a strategic approach informed by industry best practices, companies can leverage this essential equipment to streamline operations effectively.

Chain conveyor belts play a crucial role in various industries, serving as vital components for efficiently transporting materials and products. The importance of these belts is underscored by a report from the Material Handling Industry of America, which indicates that effective material handling can reduce operational costs by 20-30%. This efficiency translates into significant time savings and enhanced productivity, particularly in sectors such as manufacturing, food processing, and logistics, where the seamless flow of materials is essential to meeting market demands.

Moreover, the versatility of chain conveyor belts allows industries to customize their material handling systems according to specific needs. According to a study by Research and Markets, the global market for conveyor systems is projected to grow significantly, driven by advancements in automation and the increasing adoption of smart technologies in industrial operations. These trends highlight the necessity for businesses to choose the right chain conveyor system that aligns with their operational goals and enhances overall efficiency.

As industries continue to evolve, investing in high-quality chain conveyor belts will remain a key factor in maintaining competitive advantage and meeting the challenges of modern production environments.

When it comes to selecting the right chain conveyor belt for your business, understanding your specific needs and applications is paramount. Start by assessing the type of materials you intend to transport. Different industries have varying requirements, and knowing whether you will be handling heavy loads, perishables, or hazardous materials will guide your choices. Once you've identified the nature of your goods, consider the environment in which the conveyor will operate. Factors such as temperature, humidity, and exposure to chemicals can greatly influence the durability and functionality of the belt.

Tips: Evaluate both the throughput capacity and speed requirements of your typical production cycle. A belt designed for high speeds may not be necessary for lower volume applications, which could lead to unnecessary costs. Additionally, ensure that your conveyor system is compatible with the integration of existing machinery to maximize efficiency.

Another critical aspect is the maintenance and operational ease of the conveyor belt. Selecting a belt that requires minimal maintenance can save your business time and resources in the long run. Pay attention to the design features that facilitate easy cleaning and repairs, which are essential for maintaining productivity levels, especially in industries with strict hygiene standards.

When choosing the right chain conveyor belt for your business, evaluating the materials and durability is essential. Conveyor belts face various operational challenges, including heavy loads, extreme temperatures, and abrasive materials. According to a report by the Conveyor Equipment Manufacturers Association (CEMA), the right selection of materials can reduce maintenance costs by up to 30% and enhance overall system efficiency. Common materials for chain conveyor belts include plastic, steel, and rubber, each offering distinct advantages depending on the industrial application. For example, plastic belts are lightweight and resistant to corrosion, making them ideal for food processing environments, while steel belts are perfect for handling heavy loads at elevated temperatures.

Durability is another critical factor that impacts the lifespan and efficiency of a conveyor belt. A study published in the International Journal of Engineering Research concluded that belts made from high-quality materials can last up to 30% longer than their lower-quality counterparts, translating to significant cost savings over time. Factors such as load capacity, temperature resistance, and exposure to chemicals should be thoroughly evaluated when selecting the appropriate chain conveyor belt. Furthermore, assessing the environmental conditions of your operation will help you choose a belt that withstands wear and tear, ensuring continuous productivity and reducing downtime.

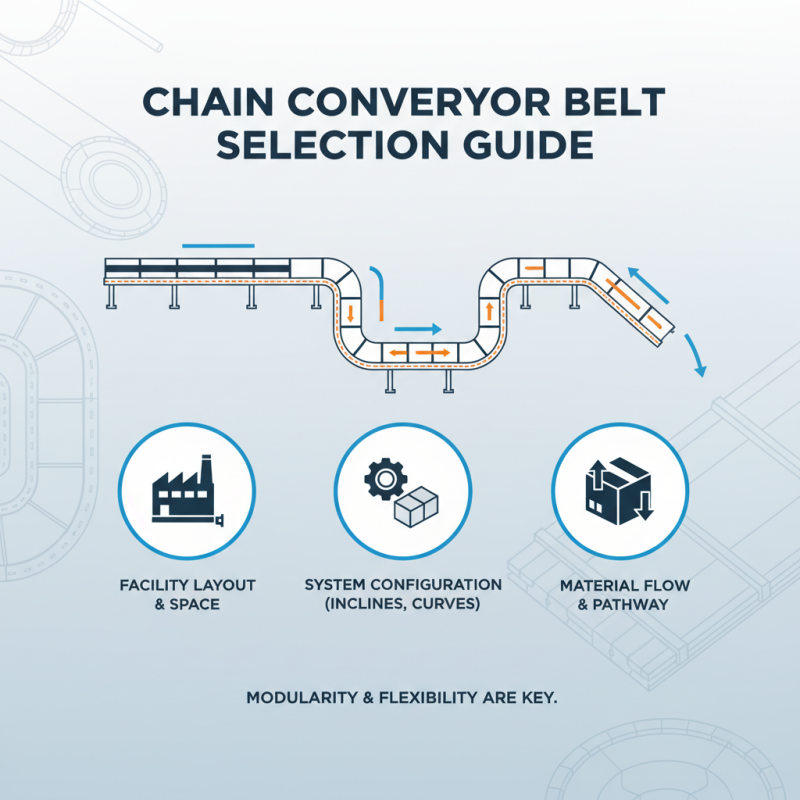

When selecting the right chain conveyor belt for your business, it’s crucial to consider various factors that influence both the size and configuration of your conveyor system. The layout of your facility plays a significant role; available space will dictate the length and width of the conveyor. If your operations require a complex pathway, such as inclines or curves, you may need to choose a modular system that can be configured to fit your specific layout.

Another critical factor is the type of materials being transported. Heavier loads may necessitate a wider belt and additional support to ensure safety and efficiency. Additionally, the temperature and environment where the conveyor will operate can influence the material choices for both the chain and the belt.

**Tip:** Always assess the maximum load capacity required for your operations to avoid potential system failures.

Finally, consider the maintenance and serviceability of the conveyor system. Systems that are easy to access and maintain can save you significant time and costs in the long run.

**Tip:** When selecting a conveyor system, prioritize designs that allow for easy upgrades and modifications, ensuring your system can adapt to future needs.

When selecting a chain conveyor belt for your business, it is crucial to prioritize maintenance and support to ensure optimal performance. Regular maintenance not only prolongs the lifespan of the conveyor system but also enhances operational efficiency. According to a report from the Conveyor Equipment Manufacturers Association (CEMA), proper maintenance can reduce downtime by up to 25%. This emphasizes the need for a systematic maintenance schedule that includes routine inspections, lubrication, and the prompt replacement of worn components. Establishing a preventive maintenance plan tailored to your specific conveyor belt system can significantly mitigate potential issues before they escalate.

Additionally, it’s vital to consider the support provided by the manufacturer or supplier. Comprehensive support services, including technical assistance and training, play an essential role in maintaining operational efficiency. A study by Research and Markets highlighted that businesses utilizing effective support frameworks for their conveyor systems reported a 30% increase in productivity. This indicates that having access to reliable customer support can guide your maintenance practices, ensuring that your workforce is well-trained to handle minor repairs and adjustments. Investing in both regular maintenance and robust support mechanisms can lead to enhanced performance and reduced operational costs over time.