In the ever-evolving landscape of industrial operations, the significance of maintaining a Wire Mesh Belt cannot be overstated. According to renowned expert Dr. Richard Lawson, a leading authority in conveyor system technologies, "Regular maintenance of your Wire Mesh Belt is not just a best practice; it's essential for ensuring longevity and peak efficiency." His insights reflect a common understanding among industry professionals that a well-maintained Wire Mesh Belt can significantly enhance operational performance and reduce costly downtimes.

As manufacturing processes become increasingly automated, the reliance on durable and efficient Wire Mesh Belts grows stronger. These belts are pivotal in applications ranging from food processing to material handling, where precision and reliability are paramount. Effective maintenance strategies are crucial—not only to uphold the functioning of these belts but also to maximize their operational lifespan. Understanding the nuances of Wire Mesh Belt care can empower facility managers and operators to adopt proactive measures that mitigate wear and tear, ultimately contributing to a more productive working environment.

In this guide, we will delve into top tips for maintaining your Wire Mesh Belt, offering practical advice that combines expert knowledge with hands-on experience. By following these guidelines, businesses can ensure that their Wire Mesh Belts perform at optimal levels, paving the way for enhanced efficiency and reduced operational costs.

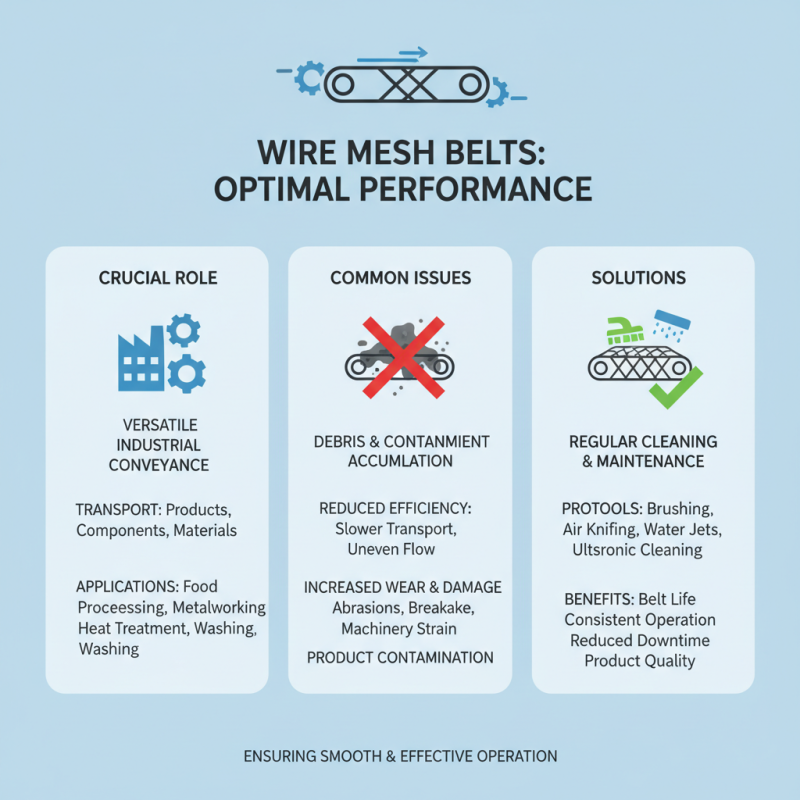

Wire mesh belts are versatile components used across various industries for material handling, processing, and transportation. These belts, typically made from stainless steel or other durable materials, feature a series of interconnected wires that create a sturdy lattice structure. Their design allows for airflow and drainage, making them ideal for applications in food processing, metallurgy, and packaging. The breathability of wire mesh belts ensures optimal drying and cooling processes, while their robustness enables them to withstand high temperatures and harsh environments.

In addition to their physical properties, wire mesh belts are highly adaptable and can be customized to meet specific operational requirements. They can be designed in various widths, lengths, and mesh patterns, catering to different materials and production processes. Common applications include conveyor systems in manufacturing plants, platforms for baking in the food industry, and filters in chemical processes. The flexibility offered by wire mesh belts allows businesses to enhance their operational efficiency while maintaining high standards of hygiene and safety in their production lines.

| Tip | Description | Frequency | Benefits |

|---|---|---|---|

| Regular Cleaning | Use appropriate cleaning solutions to remove debris and buildup. | Daily | Prevents corrosion and maintains belt integrity. |

| Inspect for Damage | Regularly check for wear, cracks, or breaks in the mesh. | Weekly | Identifies issues early to avoid costly downtimes. |

| Proper Lubrication | Use recommended lubricants on bearings and rollers. | Monthly | Reduces friction, improving overall belt efficiency. |

| Monitor Tension | Ensure belts are properly tensioned for optimal performance. | Monthly | Prevents slippage and premature wear. |

| Temperature Control | Keep operating temperatures within recommended limits. | Continuous | Maintains material properties and extends service life. |

Wire mesh belts play a crucial role in various industries, but their performance can be compromised by common issues. One frequent problem is the accumulation of debris and contaminants on the belt surface. This buildup can lead to reduced efficiency, increased wear, and potential damage to the belt and associated machinery. Regular cleaning and maintenance protocols are essential to prevent this issue, ensuring the belt operates smoothly and effectively.

Another significant concern is misalignment of the wire mesh belt. Misalignment can cause uneven wear patterns, leading to premature failure and costly downtimes. To mitigate this, it’s important to regularly check the alignment and adjust the tension as necessary. Additionally, monitoring the tracking of the belt during operation can help identify any issues before they escalate, maintaining optimal performance and extending the lifespan of the belt. Keeping an eye on these common pitfalls can significantly enhance the operational reliability of wire mesh belts.

Routine maintenance practices are vital for ensuring the optimal performance of wire mesh belts, particularly in industrial applications where these belts are integral to production processes. Regular inspection and cleaning are key components that cannot be overlooked. According to industry reports, over 30% of operational disruptions in conveyor systems are attributed to inadequate maintenance of wire mesh belts. Implementing a consistent cleaning schedule helps remove debris and contaminants that can cause wear and tear, ultimately extending the life of the belt.

One effective tip for maintaining wire mesh belts is to regularly check for any signs of damage or misalignment. This includes inspecting the belt for cracks or fraying wires, as well as ensuring it runs true without any irregular movements. Experts advise that a routine inspection should be conducted at least once a week. Additionally, lubrication of the drive components should be performed to minimize friction and prevent overheating, which can reduce the likelihood of belt failure. Proper alignment and tension are also critical, as misaligned belts can result in increased wear and even complete breakdowns.

Moreover, keeping a detailed maintenance log can significantly improve the longevity of wire mesh belts. This log should document cleaning schedules, inspections, and any repairs performed. A study found that companies that maintain meticulous records enjoy a 25% reduction in unscheduled downtime. By following these maintenance practices and incorporating these tips, businesses can ensure their wire mesh belts operate efficiently and reliably, contributing to overall productivity in their operations.

Maintaining a wire mesh belt is essential for ensuring optimal performance in various industrial applications. One of the most effective ways to prolong the life and efficiency of your belt is through regular and thorough cleaning. Depending on the environment in which the belt operates, debris, grease, and other contaminants can accumulate, leading to reduced functionality and potential wear.

Start by establishing a regular cleaning schedule that aligns with the demands of your operation. Use a combination of warm water and mild detergents for routine cleaning to prevent buildup. High-pressure water jets can also be an effective tool, particularly for belts exposed to heavy production materials. For more stubborn residues, employ soft brushes or cloths that will not damage the mesh but can effectively remove contaminants. Additionally, consider using automated cleaning systems if your setup allows; these systems can provide consistent and thorough cleaning without interrupting operations.

After cleaning, make sure to dry the belt properly to prevent any water-related issues, such as rusting or corrosion. Inspect the mesh for any signs of wear or damage during the cleaning process, as early detection can prevent more significant problems down the line. By incorporating these effective cleaning techniques into your maintenance routine, you can ensure that your wire mesh belt operates at peak performance and lasts longer in demanding industrial environments.

When it comes to ensuring the longevity and efficiency of wire mesh belts, regular inspection is paramount. Start by closely examining the belt for signs of wear and tear, including fraying, corrosion, or broken wires. Pay attention to the mesh openings; they should be free from blockages that could compromise the flow of materials. Additionally, check for any misalignment or damage to the support structures that could lead to an uneven distribution of load. Performing these inspections on a scheduled basis will help identify potential issues early and prevent costly downtime.

Replacing wire mesh belts is equally crucial for maintaining optimal performance. If wear is detected during inspections or if the belt shows signs of excessive wear or damage, it's essential to replace it promptly. Always ensure that the new belt matches the specifications required for your specific application, as differences in width, mesh size, or material can significantly affect functionality. To ease the replacement process, maintain a spare belt in stock and familiarize your team with the installation procedures. Regular inspections combined with timely replacements will greatly enhance the reliability and efficiency of your wire mesh belt system.