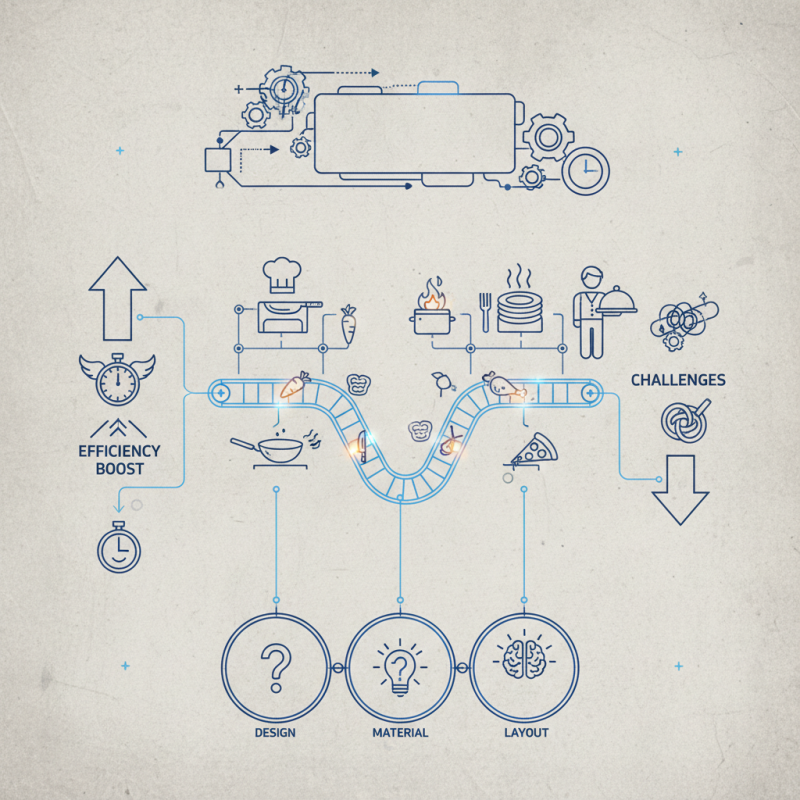

In the fast-paced world of modern kitchens, efficiency is key. One innovative solution transforming food preparation is the Food Conveyor Belt. This system allows ingredients to flow seamlessly from one station to another. As kitchen teams become busier, effective transport methods are essential.

Consider a busy restaurant during peak hours. Chefs rely on the Food Conveyor Belt to keep operations running smoothly. It minimizes the time taken to move items, enhancing productivity. However, not all systems are perfect. Some may face challenges, like tangling or uneven speeds.

Adopting a Food Conveyor Belt is an investment, but it requires careful evaluation. Kitchens must choose systems that suit their specific needs. The design, material, and layout should align with operational workflows. Reflecting on these aspects is crucial for maximizing efficiency in a modern kitchen.

Modern kitchens are increasingly integrating conveyor belt systems to streamline food preparation and service. These systems vary in design and function, catering to different culinary needs. One popular type is the flat belt conveyor. It allows seamless movement of dishes from one end of the kitchen to the other. This can enhance workflow, but it sometimes requires frequent maintenance.

Another noteworthy type is the modular conveyor belt. Made of interlocking components, it offers flexibility in configuration. It can adapt to various kitchen layouts, which is a significant advantage. However, the assembly can be complex, leading to misunderstandings among staff. Clear guidelines are essential to avoid confusion.

Moving on, the sushi conveyor belt system enhances dining experiences as well. It presents items attractively, encouraging customer engagement. Yet, if not managed properly, it can lead to food safety concerns. Regular checks and a focus on hygiene are crucial. These examples highlight the diverse applications of conveyor belts, revealing both benefits and challenges in modern culinary environments.

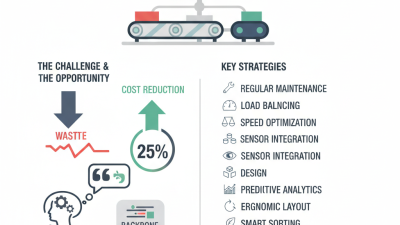

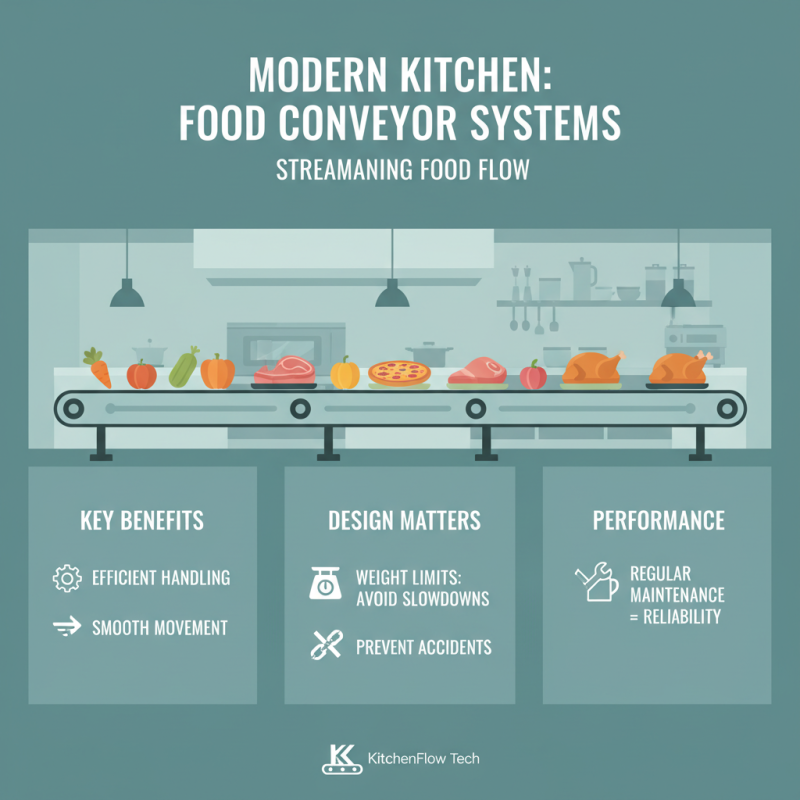

In modern kitchens, efficient food conveyor belt systems play a vital role. These systems are designed to streamline food handling processes. Proper design ensures smooth movement of ingredients and cooked meals. However, not all conveyor belts are created equal. Some systems may struggle with weight limits, leading to slowdowns and accidents. Regular maintenance is crucial for performance.

Key features of effective conveyor systems include adjustable speeds and modular designs. Adjustable speeds allow chefs to synchronize the flow with kitchen activities. Modular designs enable easy reconfiguration for different tasks. Yet, many establishments overlook regular training on these systems. Untrained staff can lead to inefficiencies and potential hazards. It's important to create a culture of awareness and training.

Another important aspect is hygiene. Conveyor belts must be easy to clean. Food residues can build up and cause issues. Systems designed with removable parts facilitate cleaning. However, some kitchens neglect these details, leading to larger problems over time. Investing in a high-quality system is wise, but running it efficiently is an ongoing challenge.

In modern kitchens, efficiency is key. Food conveyor belts can significantly streamline operations. They help move ingredients quickly to where they're needed. This reduces wait times and enhances overall productivity. Staff can focus on cooking instead of manual transport.

Tips: Ensure your conveyor belts have adjustable speed settings. This allows staff to work at their own pace. Regular maintenance is crucial too. Updating parts can prevent unexpected breakdowns. Don’t overlook training for all team members. Proper use of these systems maximizes their potential.

Implementing conveyor belts can bring about some challenges. Not every kitchen layout suits them. It may require rethinking the design. Staff may need time to adapt to these changes. However, the long-term benefits often outweigh the initial hurdles. More efficient workflows are attractive to both customers and staff.

| System Type | Application | Efficiency Gains | Cost Savings (%) | Implementation Time (Weeks) |

|---|---|---|---|---|

| Modular Conveyor Belt | Prepared Foods | 30% Faster Order Fulfillment | 15% | 4 |

| Sanitary Belt System | Bakeries | 20% Reduction in Labor Costs | 10% | 3 |

| Low-Profile Conveyor | Food Packaging | 25% Increase in Throughput | 12% | 5 |

| Incline Conveyor | Logistics and Delivery | 40% Space Utilization Improvement | 18% | 6 |

| Flat Belt Conveyor | Kitchen Assembly Lines | Reduced Food Waste by 15% | 14% | 4 |

In modern kitchens, conveyor belt systems are revolutionizing workflow. They can transport food items efficiently, reducing travel time for staff. This is particularly beneficial in busy restaurants. A case study from a bustling diner shows how a conveyor belt cut prep time by 30%. This allowed chefs to focus more on cooking rather than moving ingredients.

Another successful implementation took place in a catering company. They used a conveyor belt for assembling meals quickly. This system minimized human error and wasted time. Staff reported less fatigue, as they no longer had to carry heavy trays. However, the initial setup took longer than expected. It required careful planning and training to integrate seamlessly.

Tips for implementing a conveyor system: Start with a clear layout plan. Ensure the system fits your kitchen's flow. Train your team thoroughly to minimize mistakes. Be prepared to troubleshoot issues and gather feedback regularly. Continuous adjustment will keep the system efficient.

In modern kitchens, food conveyor technology is rapidly evolving. As food service demands increase, efficiency becomes paramount. According to recent industry reports, kitchens equipped with conveyor belt systems can boost productivity by up to 40%. This improvement is significant for restaurants and food facilities racing against time.

Innovative designs enhance the flow of operations. For instance, modular conveyor systems allow for easy reconfiguration. A study highlights that nearly 30% of kitchen space can be used more effectively with these systems. However, integrating such technology requires thoughtful planning. Not all kitchens have the infrastructure to support advanced conveyor systems.

Yet, there are challenges. Maintenance can be complicated. Systems need regular checks to prevent downtime, a costly setback. Many operators overlook this aspect. Reliability is key in high-volume environments. As kitchens adapt to these trends, balancing efficiency with proper upkeep becomes a strategic necessity. The future will likely see more adaptable systems that merge seamlessly with kitchen workflows.