Steel Wire Mesh has become a crucial component in modern construction. According to John Smith, a renowned expert in the field, "Steel Wire Mesh strengthens structures significantly." Its versatility is evident in various projects, from bridges to buildings. This material provides essential reinforcement, ensuring stability and durability.

Incorporating Steel Wire Mesh requires careful planning. It is not just about using it; the installation process matters. For example, spacing and layering can affect performance. Construction teams must evaluate their designs thoroughly. This exploration can reveal potential flaws or areas for improvement.

Despite its advantages, challenges exist. Poor-quality mesh can lead to structural failures. It's essential to source materials from reputable suppliers. A thoughtful approach is necessary to avoid mistakes. Using Steel Wire Mesh effectively can enhance any project when done correctly.

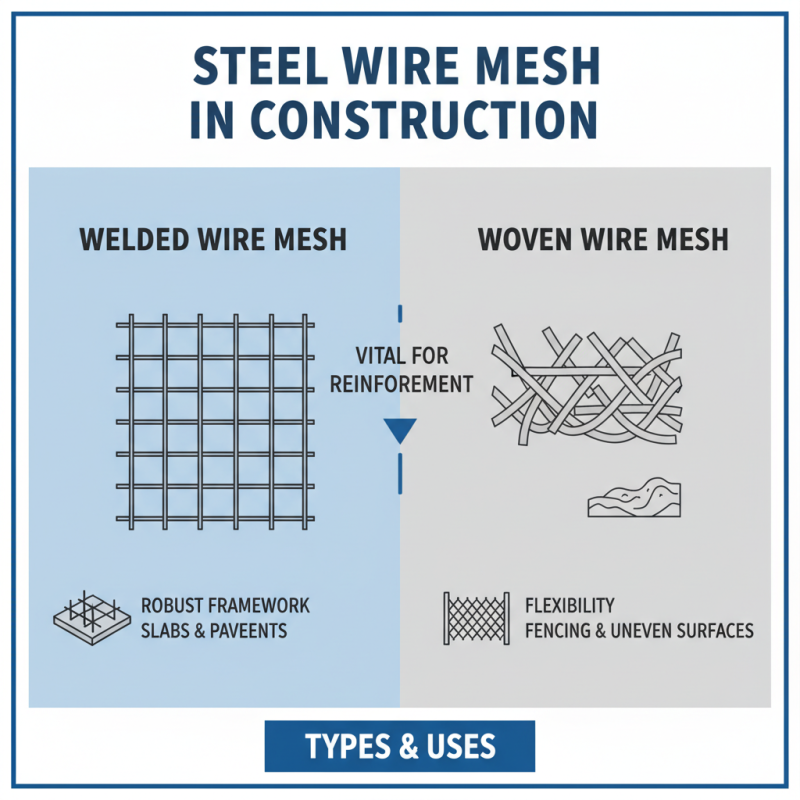

Steel wire mesh is vital in construction projects. Several types cater to different needs. Common types include welded wire mesh and woven wire mesh. Welded wire mesh consists of intersecting wires, providing a robust framework. It is often used in slabs and pavements. On the other hand, woven wire mesh offers flexibility, which is beneficial for fencing and reinforcing uneven surfaces.

Specifications matter when choosing wire mesh. The gauge, or thickness, influences strength. A lower gauge indicates a thicker wire. Typically, gauges range from 8 to 20. The spacing between wires also varies. Closer spacing usually provides better support. Yet, it may increase costs. Size and shape can also differ. Customizing mesh can enhance performance in specific projects.

Reflecting on the selection process is crucial. Misjudging the type or specification can lead to failures. For instance, using a lighter gauge in heavy loads might result in cracks. Evaluating the project's demands thoroughly can prevent such mistakes. Understanding these elements helps ensure a successful construction outcome.

Steel wire mesh is crucial in construction. Its tensile strength is vital for reinforced concrete. Studies show that using steel wire mesh can improve the flexural strength of concrete by up to 50%. This makes it a preferred choice in building structures that demand durability.

The properties of steel wire mesh enhance its role in reinforcement applications. Its high tensile strength offers resistance to cracking. Meanwhile, its lightweight design makes it easy to handle and install. According to recent industry reports, projects using steel wire mesh experience a 30% reduction in weight, facilitating quicker assembly. However, inadequate installation can compromise its benefits.

Moreover, steel wire mesh has excellent conductivity. This property is vital in grounding applications. Yet, some projects overlook this aspect, leading to safety risks. It's essential to consider all properties before using steel wire mesh in any construction project. Proper evaluation and application are key to maximizing its effectiveness.

Steel wire mesh plays a crucial role in enhancing the strength of concrete structures. When used properly, it prevents cracking and ensures longevity. One of the best practices is to ensure proper placement within the concrete mix. Positioning the mesh at the mid-depth of the slab can maximize its effectiveness. It should not be exposed on the surface. Adjust the mesh to fit snugly into the formwork, avoiding overlaps. This simple yet vital step can significantly elevate the performance of the final structure.

Another key aspect is the correct connection of mesh sheets. Overlapping separate pieces can lead to weak points. Secure them with tie wires to create a continuous reinforcement layer. This minimizes the risk of structural failure. Workers should take care when cutting mesh to avoid sharp edges. These edges can pose safety hazards. Regular checks during installation can catch mistakes early, reducing costly corrections later on. Awareness of these details transforms the outcome of a construction project, reflecting a commitment to quality and safety.

When it comes to installation techniques for steel wire mesh in concrete works, attention to detail is crucial. Proper alignment and spacing are essential to ensure that the mesh can effectively distribute stresses. According to the American Concrete Institute, using properly placed steel wire mesh can enhance concrete tensile strength by up to 50%. Misalignment can lead to weaknesses, making it vital to follow best practices.

During installation, ensure the mesh is raised slightly off the ground. This allows concrete to fully encase the wire, creating a stronger bond. Proper support is necessary, as the mesh should not sag. Many professionals recommend using chairs or spacers to maintain the correct height. Failure to do this may compromise the overall integrity of the concrete structure.

Another critical aspect is the overlap of the mesh sheets. Reports indicate that overlapping by at least 2 to 3 inches significantly improves load distribution. However, some contractors may overlook this, resulting in a weaker structure. It’s essential to ensure that all overlaps are properly tied together, preventing any potential shifting during the pouring process. Regular inspections during installation can help catch these issues early, avoiding costly mistakes later.

| Dimension | Type of Mesh | Use Case | Installation Method | Benefits |

|---|---|---|---|---|

| 6"x6" | Steel Welded Wire Mesh | Slabs | Placed in fresh concrete | Increased tensile strength |

| 4"x4" | Steel Wire Mesh | Sidewalls | Tie with rebars | Improved crack resistance |

| 2"x2" | Fiberglass Reinforced Mesh | Pool Decks | Layer above base | Lightweight and rust-resistant |

| 1"x1" | Plastic Coated Wire Mesh | Landscaping | Secure with stakes | Corrosion protection |

| 10"x10" | Galvanized Steel Mesh | Driveways | Position before pouring | High durability and strength |

When using steel wire mesh in construction, safety standards are crucial. Compliance ensures the mesh can withstand significant weight and pressure. For projects, verify that your steel wire mesh meets local regulations. Inspect the mesh for defects before use. This prevents future structural issues.

Tips: Always wear protective gear when handling steel wire mesh. Gloves and eye protection are essential. Be aware of sharp edges. Consider the environment where the mesh will be installed. Weather conditions can affect performance.

Take care to follow industry standards. Avoid shortcuts during installation. Misalignment can lead to weak spots. If unsure, consult with a professional. This extra step can save time and resources later. Assess the installation process regularly. Reinforcement shouldn't be an afterthought. Plan carefully to avoid last-minute problems.