Wire mesh is a versatile product widely used in various industries. According to a report by Market Research Future, the global wire mesh market is projected to reach $9.5 billion by 2025. This growth is driven by demand in construction, agriculture, and manufacturing sectors. Wire mesh serves critical purposes, such as providing structural support, filtration, and safety features.

In construction, wire mesh strengthens concrete and prevents cracking. It is essential for reinforcing beams, slabs, and walls. In agriculture, it acts as a protective barrier for crops, preventing pest infestations. This application highlights its importance in ensuring food security. Furthermore, industries utilize wire mesh for screening and separation processes, enhancing efficiency in manufacturing.

However, not all wire mesh products meet the required standards. Some manufacturers cut corners, which can lead to safety issues. Attention to material quality is key. Businesses must be diligent in selecting suppliers. The challenges in the wire mesh industry call for ongoing review and improvements in practices. Prioritizing safety and effectiveness will ultimately lead to better outcomes for all sectors involved.

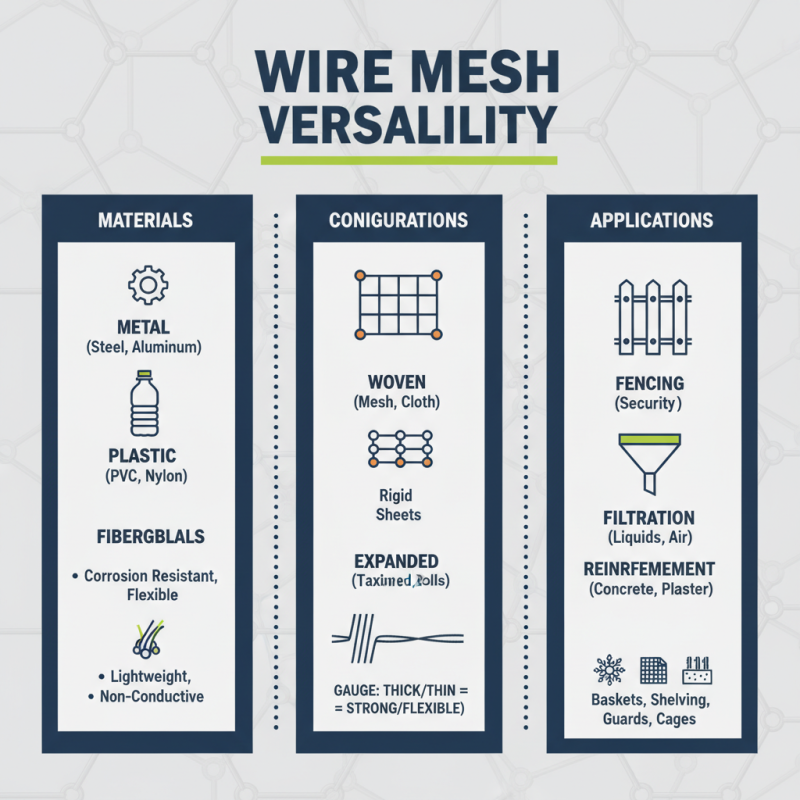

Wire mesh is a versatile material made from interconnected strands of wire. It comes in various sizes and configurations, making it suitable for a variety of applications. This mesh can be made from metal, plastic, or fiberglass, each offering unique properties. The wire's gauge can vary, affecting its strength and flexibility. Common uses include fencing, filtration, and reinforcement.

In construction, wire mesh is often used to reinforce concrete. It enhances the strength of structures and prevents cracking. In agricultural settings, wire mesh acts as fencing to protect crops from animals. It also serves as a support for climbing plants and can be found in greenhouses. In a more industrial context, wire mesh is essential for filtering materials, ensuring the purity of products in food and chemical processing.

While wire mesh proves useful, it’s important to consider its limitations. Not all types are suitable for every application. Corrosion can affect metal wire mesh when exposed to harsh environments. Sometimes, the wire spacing may not meet specific needs. In such cases, customization is necessary. This reflects the importance of choosing the right type of wire mesh for each unique situation.

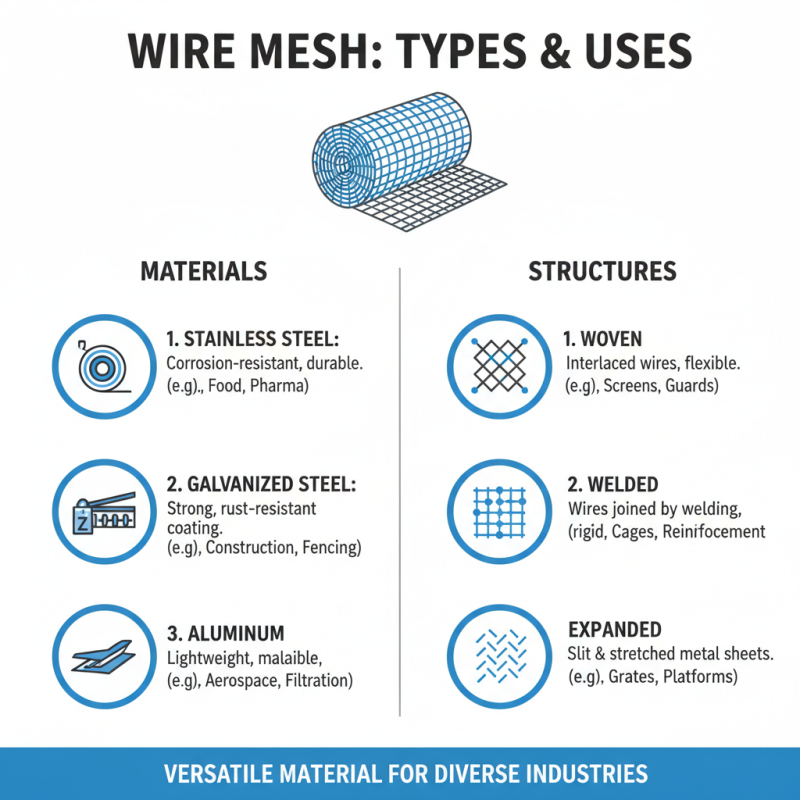

Wire mesh is a versatile material used across various industries. The types of wire mesh depend on the materials and structures used to create them. Common materials include stainless steel, galvanized steel, and aluminum. Each material offers unique properties suitable for different applications.

Stainless steel wire mesh is resilient, resistant to corrosion, and ideal for food processing and medical applications. Galvanized steel is often used in construction for its strength and affordability. Aluminum wire mesh, being lightweight, is commonly found in filtration systems and security applications.

**Tips:** For optimal usage, consider the environment where the mesh will be applied. Stainless steel performs better in wet conditions. Galvanized options might rust over time if exposed to certain chemicals.

The structure of wire mesh also varies. It can be welded or woven. Welded mesh tends to be more durable and secure, making it ideal for heavy-duty projects. Woven mesh offers flexibility and is often used for lighter tasks.

**Tips:** Assess the load requirements of your project. If you're unsure, consult a professional. The right type can save time and money in the long run. Always double-check the mesh’s specifications before purchasing.

Wire mesh is a versatile material utilized across many industries. Its manufacturing processes are crucial in determining the quality and application of the final product. The creation of wire mesh typically begins with wire drawing, where larger metal rods are reduced in diameter. This process affects the wire's strength and conductivity.

Welding is the next step. Intersecting wires are fused at various points to form a mesh. This method can vary, influencing the mesh's structural integrity. Sometimes, it may not create a strong bond, leading to a weak final product. A careful balance between temperature and pressure is necessary here.

After welding, the mesh undergoes finishing processes. These may include coating for corrosion resistance or cutting to specific sizes. Mistakes in these stages can limit functionality. Proper attention is critical to ensure that the wire mesh meets industry standards. A flaw in any process might lead to costly repercussions in real-world applications.

Wire mesh is a versatile material used in construction and architecture. It is made from interwoven wires, forming a grid-like structure. This allows it to provide support, safety, and security in various applications. One common use is as reinforcement in concrete. It helps distribute weight evenly, preventing cracks and enhancing durability.

In architectural designs, wire mesh can serve an aesthetic purpose. It offers transparency while still providing a barrier. Designers often utilize it in facades and balustrades. The interplay of light and shadow creates visual interest. Additionally, wire mesh can be crafted into unique patterns, adding character to buildings.

However, there are considerations to keep in mind. The durability of wire mesh depends on material quality. Corrosion can occur without proper treatment. Maintenance is necessary to ensure longevity. Architects must balance functionality with aesthetic appeal. Using wire mesh effectively requires careful planning and reflection on its limitations.

| Industry | Application | Material Used | Benefits |

|---|---|---|---|

| Construction | Reinforcement for concrete | Steel wire mesh | Increases tensile strength |

| Architecture | Decorative facades | Stainless steel mesh | Aesthetic appeal, durability |

| Mining | Support and ventilation | High-tensile steel mesh | Safety and stability |

| Agriculture | Fencing and trellising | Galvanized wire mesh | Effective pest control |

| Automotive | Component manufacturing | Aluminum mesh | Weight reduction, strength |

Wire mesh is a versatile material extensively used in agriculture and food processing. In farming, it serves as fencing to protect crops from animals. Farmers often use it for trellises and support structures for climbing plants. This enhances plant growth and increases yield. Proper installation of wire mesh can safeguard plants, but neglect might lead to crop loss.

In food processing, wire mesh is crucial for filtering and sorting. It's employed in the production of baked goods and dairy items. For example, mesh screens aid in sieving flour and separating curds from whey. These processes require precision, and a flawed mesh can affect product quality. Regular maintenance of these materials is essential to ensure cleanliness and functionality. Yet, many overlook this aspect, risking contamination and inefficiency.

The use of wire mesh in these sectors is significant. It helps in increasing efficiency and productivity. However, improper use can lead to challenges. Observing the effectiveness of wire mesh in real-world applications can guide better practices. Continuous evaluation will yield better results in these critical industries.