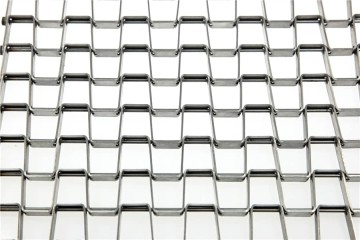

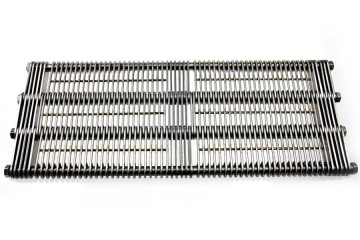

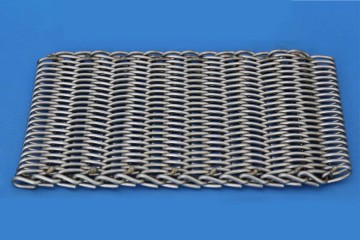

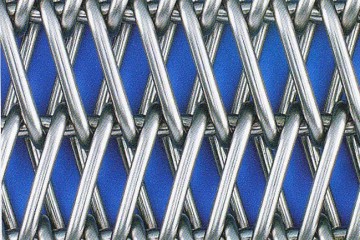

High-Quality Custom Wire Mesh Conveyor Chains Manufacturers & Exporters Worldwide

For reliable and durable Wire Mesh Conveyor Chains, trust our expertise. As a premier manufacturer, we provide tailored solutions for OEM clients. Our chains are designed with high-quality materials and advanced technology, ensuring they meet your precise industrial requirements. At JIANGSU HUADA METAL MESH BELT CO., LTD., we emphasize quality and service. Our factory can handle production volumes ranging from small batches to large orders, all while upholding stringent quality standards. Choosing our Wire Mesh Conveyor Chains ensures you benefit from durability and efficiency, essential for your operations. Connect with us to learn how we can assist your business with our product offerings tailored to your conveyor system needs.

Step-by-Step Guide To Wire Mesh Conveyor Chain Service Your Trusted OEM Partner

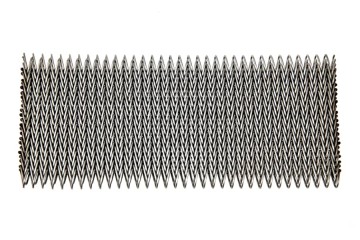

At JIANGSU HUADA METAL MESH BELT CO., LTD., we take pride in being a leading metal conveyor belt manufacturer in China, consistently supplying high-quality wire Mesh Belts and chain-driven systems to our clients around the world. With a strong commitment to precision engineering, our ISO 9001 and CE certified production facilities ensure that every product we deliver meets the highest international standards. This blog will provide you with a step-by-step guide to servicing your wire mesh conveyor chain, highlighting the importance of maintenance to achieve optimal performance and longevity. Servicing your wire mesh conveyor chain involves several key steps. First, regular inspections are essential. Check for signs of wear and tear, such as frayed wires or loose connections, which can affect functionality. Ensure that all components are clean and free from debris to prevent blockages that could hinder operation. Next, lubrication is crucial. Apply appropriate lubricants to the chain and ensure that all moving parts are well-greased to reduce friction and wear. Furthermore, alignment should be addressed; misalignment can lead to premature wear, so it’s vital to adjust the conveyor to its correct position. Lastly, document your service schedule, maintaining a log of inspections and repairs to track the performance and extend the lifespan of your equipment. As your trusted OEM partner, HUADA is dedicated to providing exceptional support and expertise in wire mesh conveyor solutions. Whether you're operating in food processing, automotive, or packaging industries, our products can be tailored to meet your specific needs. By following this guide and relying on HUADA’s innovative solutions, you will ensure your operations run smoothly, efficiently, and reliably for years to come. Contact us today to learn how we can support your business with our advanced conveyor technology and unmatched service.

Step-by-Step Guide To Wire Mesh Conveyor Chain Service

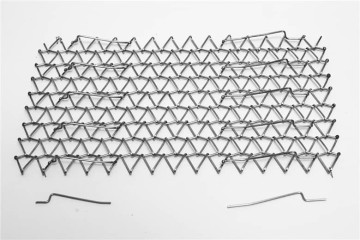

| Step | Action | Tools Required | Estimated Time |

|---|---|---|---|

| 1 | Inspect Conveyor Chain | Visual Inspection Tools | 10 mins |

| 2 | Clean the Conveyor | Brush, Cloth, Cleaning Solution | 20 mins |

| 3 | Lubricate the Chain | Lubricant, Applicator | 15 mins |

| 4 | Check Tension | Tension Gauge | 10 mins |

| 5 | Replace Damaged Links | Replacement Links, Tools | 30 mins |

| 6 | Final Inspection | Visual Inspection Tools | 10 mins |

Insider Tips For Wire Mesh Conveyor Chain Is The Best Manufacturers You Can Rely On

S

Sophia Ward

Beyond satisfied! The quality of the product combined with the stellar service made for a great purchase.

06 June 2025

A

Angela Young

Great purchase! The support staff demonstrated expertise and professionalism throughout.

12 June 2025

M

Mia Lee

Outstanding product! The support staff made my experience easy and enjoyable with their professionalism.

24 June 2025

J

Jessica Thompson

Fantastic product! The professionalism of the support staff adds great value to the experience.

11 June 2025

B

Barbara Miller

This item is of excellent quality! The service personnel were knowledgeable and amicable.

06 July 2025

V

Victoria Wilson

Incredible quality! The support staff was professional and prompt in resolving my issues.

21 June 2025