The food processing industry faces many challenges. Efficiency and quality are crucial for success. One key innovation is the Continuous Oven Mesh Belt. This technology enhances the baking process and improves overall outcomes.

The Continuous Oven Mesh Belt is designed to offer consistent heating. It supports multiple food types, from bakery goods to snacks. It can accommodate different sizes and shapes, making it versatile. However, despite its advantages, not all operations utilize it. Some facilities may hesitate to adopt new technology.

While benefits abound, there are considerations. Initial investment costs can be high. Not all staff may be trained to use it effectively. Reflecting on these aspects is important for decision-makers. Embracing the Continuous Oven Mesh Belt could transform food processing operations for the better.

Continuous oven mesh belts play a crucial role in food processing. They are designed to allow constant air flow and even heat distribution. This design leads to more uniform cooking and baking results. Food products such as bread, cookies, and snacks benefit significantly from this technology. The mesh structure ensures that heat penetrates all parts of the food evenly.

One major advantage of these belts is their durability. They can withstand high temperatures and heavy loads. However, improper maintenance can lead to issues like fraying or distortion. Regular inspections and cleanings are essential. Additionally, while they reduce cooking time, it is crucial to monitor cooking temperatures closely. Overcooking can easily occur with inconsistent settings.

Quality control should be a top priority when using continuous oven mesh belts. Aligning the belt properly can prevent unnecessary wear and tear. Failure to do so may lead to uneven cooking or product defects. Consuming inconsistent products can be problematic for both manufacturers and consumers. Proper training for staff operating these systems is beneficial. This can help avoid costly mistakes and improve overall productivity.

Continuous oven mesh belts are revolutionizing food processing technologies. They offer significant improvements in cooking efficiency. A recent industry report states that using mesh belts can reduce cooking times by up to 30%. This enables faster production rates without compromising food quality.

The design of mesh belts promotes even heat distribution. This feature minimizes the risk of uneven cooking. However, some operators report initial challenges in adjusting settings. It requires precise calibration. Mishandling can lead to inconsistent results, creating a need for ongoing training. Regular maintenance is essential to ensure optimal performance.

Another benefit is their ability to handle diverse food products. Mesh belts can accommodate a range of shapes and sizes. They support continuous flow, reducing bottlenecks in processing lines. However, transitioning to mesh belts can be costly. Companies must weigh the initial investment against long-term savings. Balancing efficiency and cost is crucial for success in food processing.

In the food processing industry, improved heat distribution and cooking uniformity are critical for achieving consistent quality. Continuous oven mesh belts provide significant benefits in this area. According to industry reports, using a mesh belt can increase cooking efficiency by up to 30%. This efficiency arises because heat is evenly circulated, reducing hot and cold spots that often lead to unevenly cooked products.

One of the standout features of mesh belts is their ability to accommodate various food items. For example, when cooking baked goods, the consistent airflow allows for even browning. This is essential in avoiding overcooked edges and undercooked centers. A study by the Food Industry Research Group highlighted that uniform cooking reduced product rejection rates by nearly 15%. This demonstrates the cost-saving potential of investing in advanced cooking systems.

**Tip:** Regular maintenance of the mesh belt can enhance its performance. Ensure that the belt is cleaned properly to avoid buildup that can hinder heat transfer.

Another advantage is the adaptability of these systems. They can handle multiple cooking processes, from baking to roasting. However, challenges may arise with certain food types that have different moisture levels. It’s essential to monitor these variables closely.

**Tip:** Test various cooking times and temperatures. Conducting small batches can help find the perfect balance, thus minimizing the risk of food waste.

| Benefit | Description | Impact on Food Quality | Operational Efficiency |

|---|---|---|---|

| Improved Heat Distribution | Ensures even cooking by allowing hot air to circulate uniformly. | Reduces undercooked or burnt food. | Minimizes cooking time, leading to higher throughput. |

| Cooking Uniformity | Delivers consistent cooking results regardless of item shape or size. | Enhances product quality and consumer satisfaction. | Streamlines production processes, reducing rework. |

| Energy Efficiency | Optimizes energy use by maintaining steady heat levels. | Results in cost savings and reduced environmental impact. | Enhances profit margins through lower operating costs. |

| Versatility | Suitable for a wide range of food products, including delicate items. | Increases product range and market competitiveness. | Facilitates easy transitions between different types of food products. |

| Durability and Easy Maintenance | Made from robust materials to withstand high temperatures. | Ensures longer product life and reliability. | Reduces downtime and maintenance costs. |

Continuous oven mesh belts are transforming the food processing industry. One notable advantage is the reduction of food waste. These belts allow for uniform heating, ensuring that every piece of food is cooked evenly. This means fewer undercooked or overcooked items end up discarded. Wasted food translates directly into wasted resources, which is something to consider.

Energy consumption is another critical factor. Continuous ovens are designed to be more efficient than traditional methods. They maintain consistent temperatures with less energy fluctuation. This steadiness not only preserves food quality but also enhances energy savings. It's vital for businesses to track their energy usage. Minor adjustments can lead to significant reductions in bills.

**Tip:** Regular maintenance of your oven can prevent energy loss. Check for leaks or insulation wear, which might increase energy consumption.

Moreover, staff training is essential. Ensuring everyone understands the importance of optimal cooking times can help minimize waste. Food processing has room for improvement, and focusing on these aspects will benefit all.

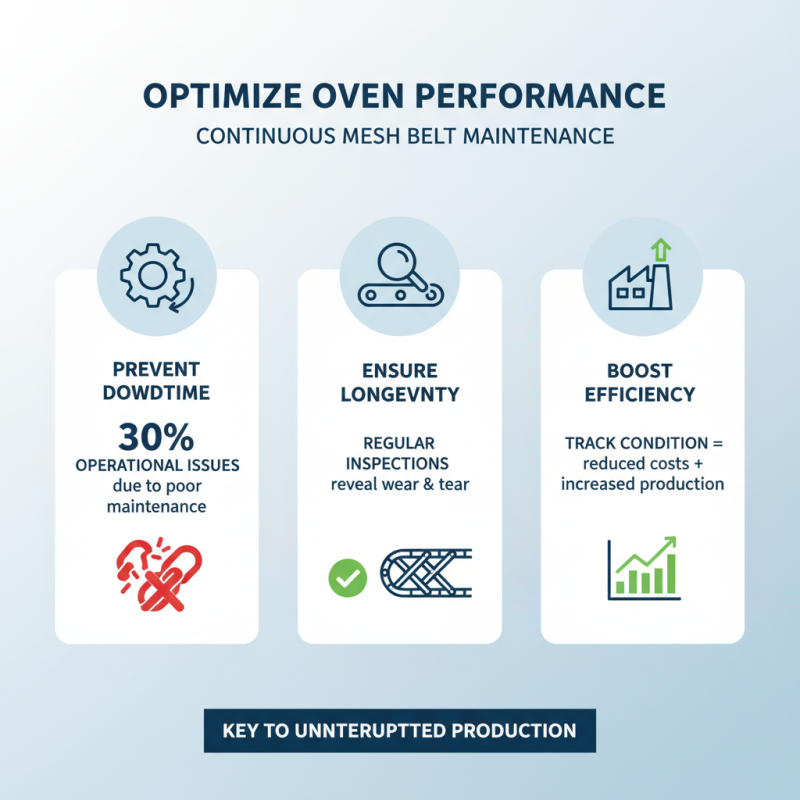

Maintenance is crucial for the longevity of continuous oven mesh belts. Regular inspections help identify wear and tear. According to industry studies, nearly 30% of operational issues stem from inadequate maintenance. This can lead to costly downtime and reduced production efficiency. Tracking the condition of the mesh belt can prevent such problems.

Proper cleaning is often overlooked. Residue build-up can cause friction and result in premature belt failure. A report by the Food Processing Institute noted that cleaning protocols can extend belt life by up to 25%. This highlights the importance of incorporating effective cleaning routines. It is essential to use non-corrosive materials to avoid damaging the belt.

Lubrication plays a significant role as well. While some operators may neglect this, a well-lubricated belt can operate smoothly and last longer. However, excessive lubrication can attract contaminants, leading to other complications. Striking a balance is key. Regular training on maintenance practices may also improve overall efficiency. This is an area where many facilities still need improvement.