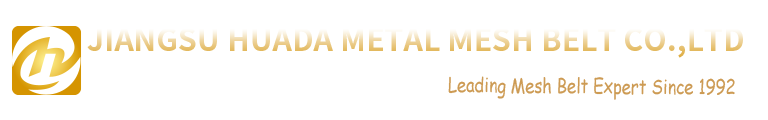

In the world of manufacturing and logistics, optimizing Transport Belt efficiency is crucial. According to a recent report by Logistics Management, companies can reduce operational costs by up to 25% by improving their transport system. Despite these potential gains, many facilities still underutilize their Transport Belts, leading to wastage.

Industry expert Dr. Ethan Rivers believes, "A well-optimized Transport Belt system can be the backbone of any efficient manufacturing process." His insights highlight the need for continuous improvement in Transport Belt design and operation. Implementing best practices can enhance material flow and minimize downtime.

Neglecting Transport Belt efficiency can lead to significant bottlenecks. Many operations fail to realize that minor adjustments and regular maintenance can make a big difference. Companies that overlook these aspects may experience higher costs and decreased productivity. Therefore, reflecting on current Transport Belt usage is essential for industry leaders aiming to enhance their operations.

Transport belt systems are fundamental in many industries. These systems move materials efficiently. Understanding their components is crucial. A transport belt typically consists of a belt, pulleys, and rollers. Each part plays a key role in performance. Ensure the belt is the right size. A gap between the belt and pulleys can cause slippage.

One common mistake is improper tension. A belt that is too tight can wear out quickly. Conversely, if it’s too loose, it won’t convey materials effectively. Regular maintenance is necessary. Check for wear and tear. Also, observe how the belt runs. Is it smooth? Any unusual sounds could indicate issues. You might need to adjust the alignment or replace parts.

Efficient design can make a difference. Consider the load capacity and speed. Use the right materials to enhance durability. Different products may require specific belt types. Take time to analyze your system. You may find areas needing improvement. Balancing efficiency and cost is always challenging. Adjustments might lead to unforeseen consequences. Aim for gradual changes, allowing time for reflection.

Transport belts play a crucial role in many industries. Their efficiency influences production rates directly. Several factors affect how well these belts perform. The materials used in both the belt and its rollers can impact friction and lifespan. Better materials can lead to smoother operations.

Proper alignment is another vital factor. Misalignment causes wear and tear. It can also lead to unscheduled downtimes. Regular maintenance is essential to keep the system running smoothly. Neglecting this aspect often results in efficiency losses. Small misalignments can grow into serious issues over time.

Load distribution also plays an important role. Uneven loads can stress one area of the belt. This stress can lead to premature failures. Regularly checking the load balance helps mitigate this problem. Operators often overlook this detail. Training staff on these nuances can make a significant difference. An informed team is more likely to notice and address efficiency issues promptly.

| Tip No. | Optimization Factor | Description | Impact on Efficiency (%) |

|---|---|---|---|

| 1 | Belt Tension | Adjusting the tension to optimal levels ensures smooth operation. | 15 |

| 2 | Alignment | Keeping the belt aligned reduces side loading and wear. | 10 |

| 3 | Carry Roller Condition | Regularly maintaining rollers can prevent downtime. | 12 |

| 4 | Belt Material | Using the correct material for the load can improve efficiency. | 20 |

| 5 | Load Distribution | Even distribution of loads prevents overloading. | 18 |

| 6 | Speed Control | Adjusting speed for optimal transport time and load handling. | 16 |

| 7 | Regular Maintenance | Scheduled maintenance to mitigate wear and tear. | 25 |

| 8 | Dust and Contamination | Keeping belts clean improves friction and longevity. | 10 |

| 9 | Driving Mechanism | Efficient drives reduce energy consumption and improve performance. | 17 |

| 10 | Operator Training | Well-trained operators enhance overall efficiency. | 14 |

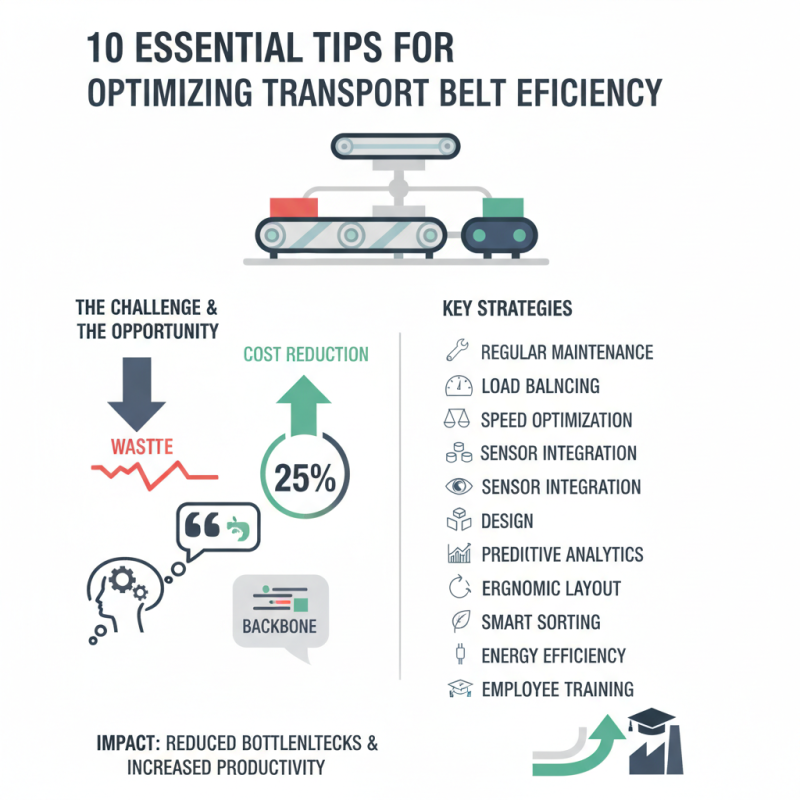

Regular maintenance of your transport belt is crucial for optimal efficiency. Check for wear and tear regularly. A small crack can lead to bigger problems. Keep the tracks clean. Debris buildup can cause friction. This friction reduces efficiency. It is essential to monitor the belt tension. Too tight can damage the belt. Too loose can create slippage. Find the right balance.

Lubrication plays a key role in performance. Use proper lubrication methods to reduce wear. However, over-lubricating can invite dust and dirt. This combination can be harmful. Inspect alignment frequently. Misalignment can lead to uneven wear, wasting resources. Track the performance over time. Noticing patterns can help pinpoint issues before they escalate.

Training staff on proper usage is important too. An inexperienced operator may not notice subtle changes in performance. Encourage regular feedback. Sometimes, a fresh set of eyes can uncover hidden problems. Address issues as they arise. Delay can result in more significant issues later. This proactive approach can save both time and money.

When designing transport belts, strategic choices greatly impact efficiency. A well-configured belt can enhance production rates significantly. According to industry studies, up to 30% of system inefficiencies are linked to suboptimal belt layouts. This highlights the importance of thoughtful design in boosting overall output.

Tip: Utilize curves wisely. Curved belts can save space and reduce friction. However, they may require more maintenance. Ensure to evaluate their long-term benefits versus potential downsides.

Belt width is another crucial factor. Wider belts can carry more load but may lead to increased costs. Balance load capacity with budget constraints for optimal results. Regularly review weight distribution. Uneven loads can cause premature wear. This creates a cycle of inefficiency and wasted resources.

Tip: Track performance data regularly. This practice reveals patterns and areas needing improvement. Refine your design iteratively to adapt to evolving operational needs.

This chart displays the efficiency of various transport belt configurations based on multiple factors. The data represents the performance of different designs in terms of load capacity, speed, and maintenance frequency. Optimizing these factors can lead to significant improvements in overall transport belt efficiency.

Efficient transport belt systems are vital in modern industries. Advanced technologies play a crucial role in monitoring and enhancing their performance. According to a report by McKinsey, integrating IoT sensors can improve efficiency by up to 15%. These sensors provide real-time feedback, helping operators make informed decisions.

One essential tip is to implement vibration analysis. Analyzing vibrations can pinpoint issues before they escalate. Early recognition of a problem saves time and reduces downtime. Additionally, using thermal imaging can identify overheating parts, which may lead to failure.

Data analytics should not be overlooked. By analyzing operational data, companies can identify bottlenecks. Inefficiencies are often hidden in data, waiting to be discovered. Another effective method involves conducting routine maintenance checks. Neglected belts can degrade quickly, leading to reduced performance.

Consider the environmental impact too. Transitioning to energy-efficient motors can lower energy consumption. Reports indicate that energy costs constitute around 25% of operational expenses in some industries. Always reflect on areas needing improvement. Efficiency is an ongoing journey, not a final destination.