In today's fast-paced food production industry, efficiency is paramount. The Food Conveyor Belt plays a critical role in streamlining operations. According to a report by IBISWorld, the food manufacturing industry generated over $780 billion in revenue in 2020. A significant portion of this success hinges on effective material handling systems such as conveyor belts.

Food Conveyor Belts enhance productivity by allowing items to move seamlessly between different stages of the production line. They reduce manual labor and minimize the risk of contamination. As reported by Grand View Research, the global conveyor systems market is projected to reach $9.5 billion by 2027. This trend reflects the increasing need for operational efficiency. However, not all conveyor systems meet the strict hygiene standards of the food industry. Proper maintenance is often overlooked, leading to potential risks.

While Food Conveyor Belts bring numerous advantages, there are areas requiring improvement. For instance, energy consumption can be significant. Companies must strive for sustainable practices without compromising safety and performance. Balancing these elements proves challenging, yet it is crucial for long-term success in food production.

Food conveyor belts play a crucial role in modern food processing. They increase efficiency in production lines. According to a 2021 industry report, 70% of food manufacturers use conveyor belts to streamline operations. These systems transport raw materials and finished products effortlessly. This reduces the risk of contamination and improves hygiene standards.

However, issues arise with wear and tear. Regular maintenance is needed to ensure optimal performance. A 2022 survey revealed that 40% of food manufacturers face downtime due to equipment failure. This can affect production timelines and lead to increased costs. Operators must regularly inspect belts for any signs of damage or dirt buildup.

Moreover, the design of conveyor belts is evolving. Many now use materials that are easier to clean and maintain. This innovation addresses food safety concerns. The Global Food Safety Initiative suggests that up to 20% of foodborne illnesses could be linked to improper handling in processing environments. Investing in modern conveyor technology can decrease these risks. But the challenge remains in balancing innovation with reliability.

In the world of food production, conveyor systems are vital. They enhance efficiency while reducing labor costs. According to a recent industry report, about 84% of food manufacturers rely on conveyor technology to streamline operations. These systems are not simply about moving items; they also ensure consistent product quality.

Key components of food conveyor systems include belts, rollers, and drives. The belt material must meet food safety standards, often made from plastic or metal. These materials resist stains and are easy to clean. Rollers help maintain tension and alignment, which are crucial for smooth operation. Drives come in various forms, including electric and pneumatic, providing flexibility in speed and power.

Despite the benefits, challenges exist. Maintenance can be overlooked, leading to breakdowns. A staggering 25% of facilities reported unplanned downtime due to conveyor issues. Regular inspections and timely replacements are often neglected. This oversight can impact production schedules and affect the bottom line. Understanding and addressing these components is essential for effective food production.

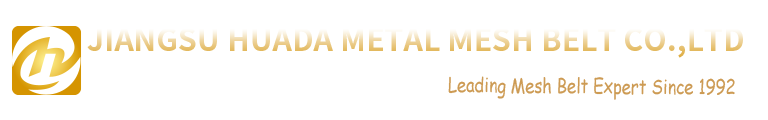

In modern food production, conveyor belts play a critical role in enhancing efficiency and safety. These systems streamline operations by moving products swiftly through various stages of processing. According to a report by IBISWorld, the use of automated conveyor systems has increased productivity in food processing facilities by up to 30%. This is significant, especially in industries where time is essential.

Safety is another crucial aspect. Food conveyor belts are often designed to meet strict health regulations. The Food Safety Modernization Act emphasizes the need for proper handling and transport of food items. A 2021 study revealed that facilities using conveyor belts had 40% fewer food contamination incidents than those using manual methods. Even minor lapses can lead to severe outcomes. Yet, some facilities still face challenges, like maintenance and cleaning of equipment.

Investments in conveyor systems can lead to high initial costs. Some small businesses hesitate to adopt these technologies. Balancing cost versus safety and efficiency is a constant dilemma. Despite these challenges, the advantages of conveyor belts in modern food production are undeniable. They promote a healthier workplace and contribute to the overall quality of food products.

In modern food production, food conveyor belts streamline processes. However, implementing these systems comes with challenges. A report by Food Processing Technology highlights that nearly 30% of operations face difficulties in maintaining hygiene standards. Regular cleaning is essential, yet time-consuming. This impact can slow production and affect product quality.

Moreover, aligning the conveyor belt system with existing workflows can be tricky. According to industry insights, over 40% of facilities struggle with this integration. Poorly planned layouts can lead to bottlenecks. In turn, this can increase operational costs and lead to employee frustration. Addressing these issues requires thoughtful planning and employee training.

There are solutions available, though. Investing in modular conveyor systems offers flexibility. These systems can be adjusted to fit various production lines. Additionally, incorporating automated cleaning technologies can maintain hygiene without halting production. Balancing efficiency and cleanliness is vital for successful food manufacturing.

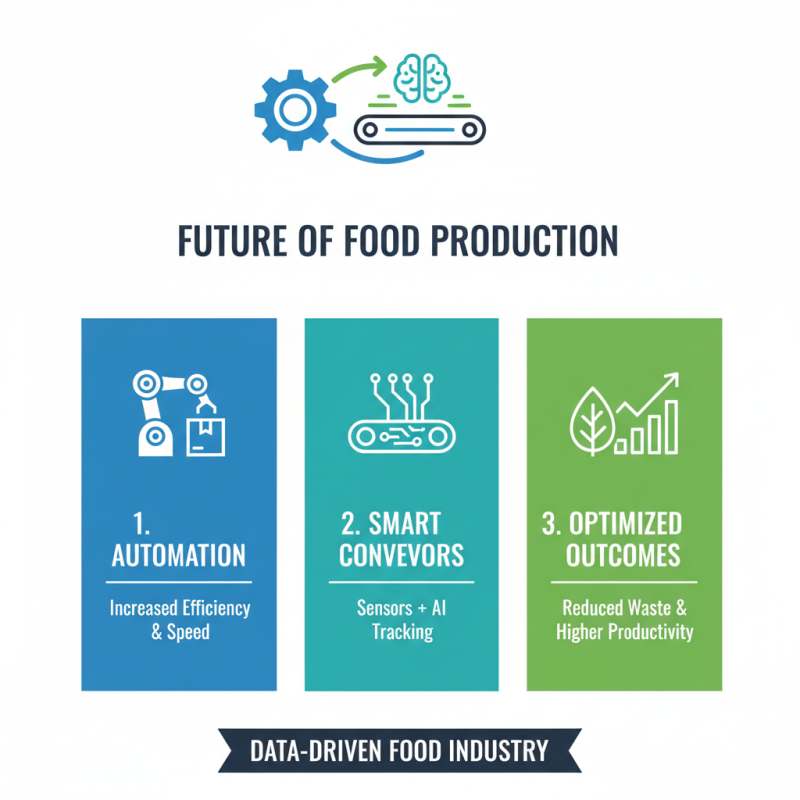

The food industry is undergoing rapid transformation. Automation is becoming crucial for efficiency. Food conveyor technology plays a significant role in this evolution. By integrating advanced sensors and AI, systems can now track the efficiency of production lines. This reduces waste and enhances productivity.

Innovative materials are entering the market. They offer improved hygiene and durability. However, they may present challenges in terms of cost and maintenance. The design of conveyor belts is also evolving. Modular systems allow for flexibility, adapting to various food items. Still, some operations struggle with adapting to these new technologies.

As production demands grow, so does the complexity of the machinery. Balancing speed and safety can be tricky. Automation sometimes leads to a lack of human oversight. This raises questions about reliability and error management. While the future looks bright, the transition requires careful thought and planning. Embracing these changes demands that industry players reflect on their current practices.