Efficient Conveyor Belt Transport is essential in today’s industrial landscape. According to a recent report by the Conveyor Equipment Manufacturers Association, optimizing conveyor systems can reduce operational costs by up to 30%. Yet, many companies overlook maintenance and design aspects, leading to inefficiencies. Expert John Smith states, “Most conveyor systems are not operating at their full potential.”

Maximizing the efficiency of Conveyor Belt Transport involves addressing several factors. It is crucial to consider load characteristics and belt speed. Improperly sized belts can result in excessive wear and higher energy consumption. Studies reveal that even minor adjustments can significantly enhance throughput and reduce energy costs.

Companies often face challenges in identifying maintenance needs. Ignoring signs of wear can lead to breakdowns and costly downtime. A focus on proactive maintenance strategies can ensure the longevity of conveyor systems. There is always room for improvement in Conveyor Belt Transport, and reevaluating existing processes is vital for success.

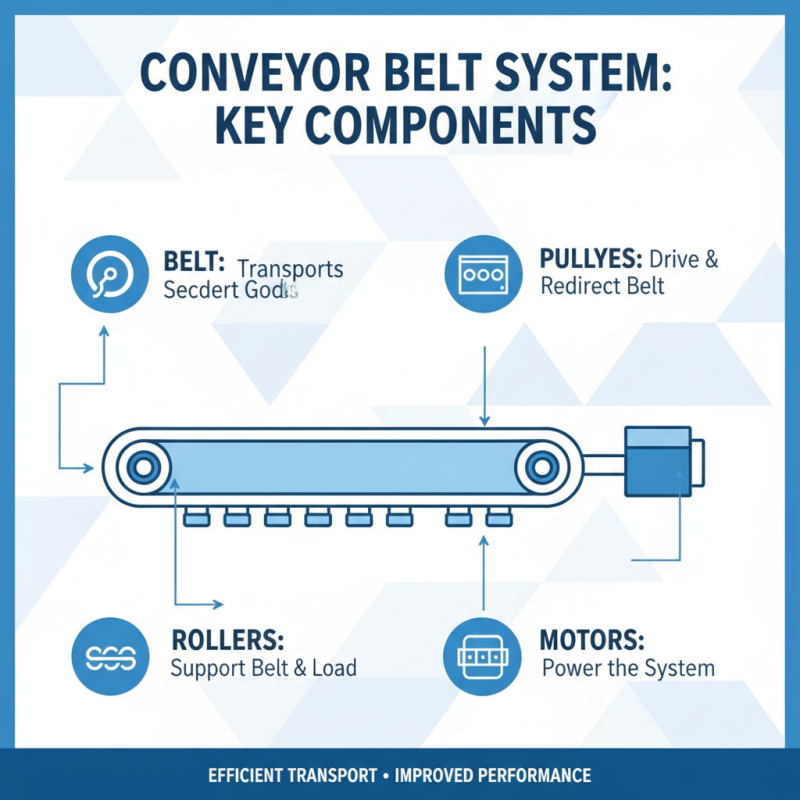

Conveyor belt systems are vital in many industries. They help transport goods quickly and efficiently. Understanding their components can improve performance. Key parts include the belt, pulleys, rollers, and motors. Each element plays a significant role in the system's functionality.

The belt acts as the main transport medium. Its durability affects the entire operation. Improper belt tension can cause excess wear. Regular maintenance is crucial to avoid breakdowns. Pulleys, the driving force behind the belt, need careful alignment. Misalignment can lead to inefficiencies and breakdowns.

Rollers support the belt and reduce friction. Selecting the right type of roller can impact energy consumption. Additionally, the motor is essential for providing needed power. A motor that is too weak can slow down the process. Many setups ignore the importance of each component. Reflecting on these aspects can lead to substantial improvements.

Conveyor belt systems play a vital role in various industries. To maximize efficiency, analyzing key performance metrics is essential. Metrics such as throughput, downtime, and energy consumption should be closely monitored. A report by the Conveyor Equipment Manufacturers Association (CEMA) suggests that optimizing these metrics can enhance productivity by up to 30%. This figure underscores the importance of data-driven decisions.

Monitoring belt speed is crucial. The optimal speed often ranges between 2.5 to 5 feet per second. If speeds are too high, product damage can occur. Conversely, slow speeds may lead to bottlenecks. A study from the International Journal of Industrial Engineering highlighted that improper speed settings could reduce efficiency by approximately 15%. Companies need to calibrate speed settings carefully.

Additionally, conveyor belt wear can significantly impact efficiency. Regular inspections and maintenance are necessary to prevent unexpected downtimes. Research shows that 60% of maintenance issues arise from neglect. Accurate tracking of belt condition can lead to proactive repairs. However, many organizations overlook this, leading to inefficiencies and increased operational costs. Continuous assessment is vital for sustained performance.

This chart illustrates the key performance metrics for conveyor belt efficiency, showcasing the relationship between speed, load capacity, and downtime.

Predictive maintenance is crucial for optimizing conveyor belt transport. It focuses on monitoring the condition of equipment in real time. By analyzing data, issues can be identified before they escalate. This proactive approach reduces unexpected downtimes. For instance, a minor belt misalignment can lead to significant delays if ignored.

Implementing predictive maintenance involves using sensors on conveyor systems. These sensors track vibrations, temperature, and performance metrics. When abnormalities arise, alerts are generated. This allows maintenance teams to act promptly. However, not every malfunction is predictable. Sometimes, the data may lead to false alarms, causing unnecessary checks.

Regular training for staff on data interpretation is vital. Properly trained personnel can differentiate between real issues and minor fluctuations. Misinterpretation can lead to wasted resources. The goal is to streamline processes while minimizing risks, maximizing efficiency in the long run. Balancing technology with skilled oversight is essential for successful outcomes.

Optimizing conveyor belt transport can significantly improve operational efficiency. Data analytics plays a crucial role in this process. By collecting real-time data, companies can identify bottlenecks and inefficiencies. Analytics can highlight patterns, revealing when and where issues arise. This enables faster responses to problems.

Implementing data-driven strategies requires commitment. Many organizations struggle with this transition. Some employees may resist changes, unsure about new technologies. Others might lack training in data analytics. Overcoming these challenges is vital for success. Continuous improvement is all about embracing these hurdles and learning from mistakes.

Regularly reviewing performance data fosters a culture of refinement. Teams can address specific weaknesses in the transport process. For instance, slow belt speeds might seem unimportant but can impact productivity. By examining minute details, organizations can optimize every aspect of their conveyor systems. Adjustments can lead to significant gains in efficiency.

Energy consumption is a critical aspect of conveyor operations. According to the International Energy Agency, conveyor systems account for a significant portion of industrial energy use. That translates to approximately 1.5% of global electricity demand. Companies need to focus on optimizing this energy consumption.

Recent studies indicate that improving drive technology can lead to efficiency gains. For instance, using variable frequency drives (VFDs) can reduce energy costs by 25% to 50%. Additionally, regular maintenance can prevent energy losses. Yet, many operators neglect this critical issue. They often overlook how minor adjustments can lead to substantial savings.

Another area to evaluate is the design of the conveyor system itself. A well-designed system can minimize friction and resistance, leading to energy efficiency. However, many facilities still use outdated designs. This leads to inefficiencies that compound over time. A lack of data analysis in operations may further exacerbate this issue. Decision-makers must develop a robust strategy. Tracking energy metrics can provide insights to enhance performance considerably.

| Conveyor Type | Energy Consumption (kWh/mile) | Load Capacity (tons) | Efficiency % | Maintenance Frequency (months) |

|---|---|---|---|---|

| Belt Conveyor | 9.0 | 30 | 85 | 6 |

| Roller Conveyor | 7.5 | 20 | 90 | 8 |

| Chain Conveyor | 10.5 | 25 | 80 | 12 |

| Magnetic Conveyor | 8.2 | 15 | 88 | 5 |

| Vertical Conveyor | 11.0 | 10 | 75 | 10 |